Launching a water station at home. Selection and installation of water pumping stations for home and garden

In terms of living conditions, private houses have always been somewhat inferior to apartments in multi-storey buildings. This mainly concerned communications, which were not present in all buildings. The problem with water supply was especially acute. Modern man fights this with the help of a pumping station.

These units are sold assembled or assembled independently. Any owner can install a pumping station; you just need to understand what kind of unit it is, how it works and where it is installed.

What you need to know to choose a pumping station

You need to choose a station based on your needs. There are two important selection factors:

- technical characteristics of the pumping station,

- distinctive features of the well.

Technical characteristics include the performance of the unit. It must provide such a water pressure that can cover its consumption both in the house and in the surrounding areas.

Practice shows that if you need to install a pumping station in a country house or in a residential building where 4 people are constantly present, it is rational to opt for devices of medium or low power. Such stations are equipped with a 20-liter hydraulic accumulator. The productivity of the station is 2-4 m 3 per hour, the pressure is 45-55 meters. This is enough to cover the needs of a family of four.

When evaluating a well, it is necessary to take into account the following indicators:

- productivity;

- size;

- water level when the pump is turned off;

- water level when the pump is running;

- type of filter;

- pipe width.

How the pumping station works

The general design of the station includes either a storage tank or a hydraulic accumulator. A unit with a storage tank is an outdated option and has many disadvantages. Firstly, the tank itself is a rather voluminous structure. Secondly, the water level and its pressure are controlled using a float, which is responsible for triggering the sensor when the water level decreases, the sensor starts pumping. Flaws:

- water leaves the system by gravity, therefore the output pressure is low;

- the entire installation is large and not always convenient for placement;

- installation of the system is complex;

- the storage tank must be installed above the station itself, which creates additional problems;

- If the water level sensor breaks down, it overflows over the edge of the tank.

Designs with a hydraulic accumulator are more reliable and practical. This installation is relatively small in size and easy to install. The system is complemented by a relay that controls the ambient air pressure limit. It compresses it in the hydraulic accumulator under the pressure of water. When the pressure level reaches the required limit, the pump automatically turns off and water from the tank is supplied to the tap. As soon as the level drops, the pump starts working again until the required level is reached.

Not only the design of the station differs, but also the pump itself. This is the device:

- with built-in ejector;

- with remote ejector;

- without ejector.

The operating principle of the ejector is that water is supplied from the well due to the vacuum created. These modifications are somewhat more expensive, but they raise water not from 9 m, like classic stations, but even from 20 or 45 m. Ejector pumps are very productive, there is only one drawback - they create a lot of noise during operation. This drawback can be mitigated by installing a pump with an ejector outside the residential premises.

Pumps with a remote ejector are convenient because the pump itself is lowered into the water intake location. Water is supplied to the ejector through a pipe in which a suction jet is created. In terms of characteristics and further operation, this design is inferior to pumps with a built-in ejector. If there is air or sand at the water intake point, this leads to rapid breakdown of the pump. The advantage of a station of this design is that it is easy to place in a house, even at a distance of 20-40 m from the home.

Pumps without ejectors supply water a little differently. Such a device has a complex multi-stage design, which relates to the hydraulic part. The ejectorless station operates silently and consumes less electricity.

These three types of pumps are the main ones; they are most often used in residential buildings. However, there are many other types of pumps on the basis of which the pumping station is installed.

Pumping station installation location

The pump is installed in the house or in a caisson. A caisson is an equipped depression in the ground. The caisson for the pump is protected from moisture, groundwater and low temperatures. It is installed under the soil freezing line. This option has a couple of significant disadvantages. Firstly, this is the need to equip this room for a pump. Secondly, it is quite difficult to insulate it in harsh climates, and under the influence of low temperatures the pump fails.

Installing a pumping station in the house is the most practical option. The optimal location is the basement. Only one factor needs to be taken into account - the likelihood of basement flooding with groundwater. If it fills with water during spring floods, the station must be placed on an elevation where it will be inaccessible to moisture. During installation, the station should not touch the walls to avoid unnecessary vibrations from its operation. The basement also monitors the room temperature at all times of the year to protect the station from frost.

When choosing an installation location, consider the following factors:

- distance from the water intake point to the station;

- humidity and temperature at the place of its installation;

- availability of free space for the convenience of performing repair and maintenance work;

- isolation of station operation noise from residential premises.

Algorithm for installing a pumping station

Do-it-yourself installation of a pumping station consists of the following steps:

- Digging trenches for pipes, it must have a slope relative to the place of water intake.

- Equipment for a passage for a pipe in the wall of a house.

- Laying pipes in a trench.

- Connecting pipes to the pump.

Helpful advice: you should pay attention to the groundwater; if it is high, then the pipeline is laid above the critical level. Pipes are insulated from low temperatures.

The pump is installed on a special base. The legs are screwed to the base using anchors, this will give the entire system a stable position. Also, to dampen vibration, a rubber mat is placed under the pump.

How to install a pumping station with a remote ejector:

- Mount the ejector. It looks like a cast iron assembly with connection outlets, there are three such outlets.

- A coarse filter in the form of a mesh is attached to the lower section of this unit.

- The required length is selected and attached to the plastic socket at the top of the unit.

- The drive has two parts, each of which contains adapters. It must be assembled to the required diameter.

- A bronze coupling is put on the outlet of the squeegee; it makes the transition to the polyethylene pipe.

- To ensure the tightness of all connections, use flax or sealing tape.

- Next is laying pipes and digging trenches; they are dug below the freezing level of the soil.

- Pipes are laid in ready-made trenches, they are taken with a reserve. For the casing pipe, use a head or elbow with a smooth angle.

- The pipe and the ejector are connected via a coupling.

- The lower end of the tube is inserted into the knee at a right angle and then lowered. All free space is sealed with polyurethane foam. The pipe is attached to the 90° adapter and to the pipeline.

- The assembled ejector is lowered to the required depth at the water intake site. This value is marked at the beginning of all work; the mark is indicated at the level of the casing pipe.

- The head is strengthened on the casing pipe; for this purpose, reinforced plumbing tape is used.

Mistakes to avoid when installing a pumping station:

- When installing pipes, it is necessary to take all values with a reserve. Often during installation, all bends, turns, and the thickness of the foundation are not taken into account if the station is installed in a house.

- Tighten all parts only with a wrench; hand-tightened and insulated connections may leak.

- The hydraulic accumulator cannot be left without attention. If the pressure is below 1.2-1.5 atmospheres, it is increased using a compressor or car pump.

How to connect the station to the water supply

The need to connect a pump to a central water supply system may arise for various reasons. Often this is an imperfection of the plumbing system and low pressure in it. The installation diagram of the pumping station to the water supply looks like this:

- At the selected location, the water supply pipes are disconnected and connected to the storage tank.

- From this container, water is supplied to the pumping station.

- A pipe is led from the pump to the water supply point.

- Electrical wiring is being installed.

- The pump is adjusted and adjusted.

- Setting up equipment is about adjusting the optimal pressure in the system.

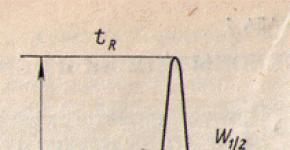

About 2 liters of water are poured into the snail and monitored at what amount the pump turns off and on. The optimal indicator for turning off is 2.5-3 bar, turning on is 1.5-1.8 bar. To adjust the pressure, use a screw marked “DR” or “P”.

A video on this topic explains in detail and clearly how to install a pumping station. Also, each manufacturer supplies its pumps with diagrams and detailed instructions. The general installation algorithm is suitable for all units, but there may be some nuances and deviations that need to be clarified before connecting.

To install or not to install a filter for a pumping station

An important factor that should be taken into account when connecting a station is the chemical composition of water and its physical qualities. Harmful impurities can be found in water from any source; they should not be allowed into the pumping station. To eliminate this problem, the device is equipped with a filter.

The filter prevents the accumulation of mechanical impurities in the accumulator and increases the service life of the pump. This is an undeniable advantage of filters.

There are also negative aspects to installing a filter. Firstly, it creates additional resistance to the flow of water, reduces pressure and pressure. Secondly, a dirty filter can completely block the access of water to the station and disable it. To avoid these troubles, the cleanliness of the filter must be monitored very carefully. In general, installing a filter is simply a necessary undertaking.

Common malfunctions in the operation of the station and their elimination

- The pump rotates, but no water enters the system. The cause of this malfunction is depressurization of pipelines; this situation also occurs due to incorrect operation of the check valve or lack of water in the system. To eliminate this problem, you need to check the presence of water in the system. If there is no water, it must be added through a special hole at the station or the depth to which the pump hose is lowered must be changed. If the problem persists after this, the valve and all connections must be checked for leaks. If this does not help, then you need to check the serviceability of the pump itself.

- The pump turns on very often and operates unevenly and jerkily. Most often, the cause of such a malfunction is damage to one of the parts of the hydraulic tank. There is a nipple on the back of the tank; if water flows after pressing it, then one of the pump membranes is torn and needs to be replaced. The cause of the malfunction may also be depressurization of the housing. If the described malfunctions are not found, then pumping air into the tank using a conventional pump can help solve the problem.

- The pump does not start. This often happens due to a lack of power. To eliminate the cause, you need to check the winding and contacts on the pressure switch.

- The pump turns on but does not rotate. The reason is a breakdown of the condenser, the impeller is stuck to the pump body. Often this situation occurs after a long break in the operation of the pump. To fix it, you need to turn the impeller several times by hand, but if this does not help, then the capacitor is broken and needs to be replaced.

- The pump operates continuously and does not pause in operation. The cause of this breakdown is a malfunction of the control relay. It must be adjusted using two springs located on the relay itself. The larger one regulates the minimum pressure, the smaller one regulates the difference between the lower and upper values. The cause may also be blockages at the relay inlet. All work with this pump part must be carried out very carefully.

To solve the water supply problem, many owners of private houses use pumping stations.

These devices are now available for sale ready-made or can be purchased separately. Moreover, every person can install a pumping station in their home. The main thing is to know what elements this device consists of, how exactly it works, how to start the pumping station and in what place it is better to install it.

What do you need to know to choose a pumping station?

In order for the selected station to cope well with its functions, the choice must be made taking into account your needs. In this regard, you can highlight the following criteria, which must be primarily taken into account by the owner:

- Technical characteristics of the pumping station;

- Features of the well.

When considering the technical characteristics, the first thing to highlight is the performance of the unit. The best option is a device capable of providing water pressure from a well, which can satisfy the needs directly in the house, as well as in the surrounding areas.

Based on practical experience, we can say that for normal living in a country house or residential building designed for 4 people, it is recommended to choose a device medium or low power. The design of such units includes a 20-liter hydraulic accumulator. Such a station is capable of supplying water from a well in an amount of 2-4 cubic meters. meters per hour and pressure 45-55 meters. An installation with such characteristics can fully satisfy the needs of a family of four.

When considering different installations, consideration should also be given to a number of other important indicators:

- productivity;

- size;

- water level when the pump is turned off;

- water level when the pump is running;

- type of filter;

- pipe width.

Any station has such a mandatory element as storage tank or hydraulic accumulator. It is worth saying that the installation with a storage tank is an outdated design due to the presence of a large number of shortcomings. First of all, the tank has a fairly large capacity. In addition, to regulate the water level and its pressure, a float is used, which ensures that the sensor is activated if the water level drops. In this case, the sensor sends a signal to turn on the pumping.

The main disadvantages the following can be mentioned:

- Water is supplied to the system naturally, which is why the pressure at the outlet is insufficient;

- Due to the large size of the unit, it is not always possible to find a suitable place to install it;

- The system installation process is accompanied by certain difficulties;

- It is important to allocate space for the storage tank at the station itself, and this is fraught with additional problems;

- If the water level sensor fails, it overflows over the edge of the tank.

Installations equipped with a hydraulic accumulator are the most reliable and practical. Their popularity is due small in size and the absence of installation difficulties. The system design contains a relay that performs the duties of regulating the ambient air pressure limit.

By creating water pressure, it is compressed in the hydraulic accumulator. At the moment when the pressure reaches the required limit, the pump automatically turns off, as a result of which water from the tank flows into the tap. If the level decreases, the pump turns on again and continues to operate until the required water level is again achieved.

For the pump, you can choose a place directly in the house or in the caisson. The last option is structure built in the ground. This design provides it with protection from moisture, groundwater and low temperatures. It must be built under the soil freezing line. However, this option has several disadvantages. First of all, such a structure requires proper arrangement. In addition, in areas where harsh climatic conditions are observed, it is difficult to insulate the caisson, as a result, when exposed to low temperatures, there is a risk of pump failure.

The most practical solution seems to be to install a pump in the house. It is best to install it in the basement. However, one important point needs to be mentioned here: you should be prepared for the fact that groundwater can create threat of basement flooding. Therefore, during spring floods, when the room is filled with water, it is recommended to install the station on a hill so that water does not reach it. You need to choose a place for the station so that it is away from the walls, which will prevent unnecessary vibrations during operation. When placing the pump in the basement, you need to constantly monitor the temperature conditions throughout the year in order to thereby protect the installation from the effects of negative temperatures.

Rules for choosing a place

To select a suitable location for a pumping station, installation in which should take place in accordance with the technology, you need based on the following criteria:

- The distance at which the station will be removed from the well;

- Temperature and humidity conditions in the location chosen for installation;

- Availability of free space so that you can easily repair and maintain the unit;

- Carrying out work to insulate the premises to limit the spread of noise towards residential premises.

Pumping station connection diagram

To properly install a pumping station with your own hands, you need stick to the following order doing this job:

A prerequisite for the installation technology of the pump is its placement on a special basis. The legs must be fixed to the base using anchors. As a result, it will be possible to ensure increased stability of the structure. To minimize vibrations, the pump should be mounted on a rubber mat.

Connecting a pumping station with your own hands in a private house with remote ejector is performed in accordance with the following algorithm:

Installation errors

During the installation of the pumping station there is risk of making mistakes:

Conclusion

Owners of private houses solve the problem of providing water somewhat differently than owners of city apartments. Having a pumping station in the house, they can always use water in the required quantity by connecting it to a well. However, to do this, you need to correctly install the pumping station in a private house with your own hands. The installation process itself does not seem so complicated, but here there are certain nuances, which many owners are most often unaware of. Therefore, you need to very carefully study the main points of station installation technology, while performing preliminary calculations.

Many owners of country houses have a question about how to provide the house and the area around it with water.

Of course, if the family is small and the dacha is used exclusively in the summer, then a regular pump will be enough.

But if the family is large and the country house remains habitable throughout the year, then you need to design an entire water supply system. To do this, you can use a pumping station, which will supply your house and area with water quickly and without problems. How to install it yourself and connect it to a well or a well in this article.

Types of equipment

Such pumping units are used in cases where the water supply comes from a well or borehole.

Divided into two types:

- automatic;

- self-priming.

Automatic pumping stations, in turn, are divided into three types:

- Vortex. Such pumps are installed only indoors, as they are very sensitive to changes in atmospheric pressure. The vortices that create pressure in the pump are created using a paddle wheel. The disadvantage of a vortex station is that a certain pressure is already required to start it.

- Centrifugal. This type of system is used for wells, as it is able to withstand temperature changes that occur in the hose. Thanks to its structure, the centrifugal station creates pressure that can lift water from very great depths.

- Sewer. Such installations are very large in size and consist of pumps, sensors, filters and pipelines.

Good to know: Centrifugal and sewage pumping stations are submersible. They are used when water is deep underground.

How to properly mount to a well or borehole

The first thing you need to do is determine where the pumping station will be located.

This can be a room inside the house (for example, a basement) or a coffer (this is a waterproof chamber that is located outside the house).

In order to connect the system to a well or borehole you must:

- The station legs must be attached to the surface. This is done using a special fastener - an anchor.

- Lower the hose into the well (well). You need to be careful not to lower the hose to the very bottom, so that when pumping out water, various debris and dirt do not get into it. It is enough to raise it one meter from the bottom of the well.

- One end of a polyethylene pipe is required, which is placed in a well or well. But, before lowering it, it is necessary to attach a coupling (connecting element) to the pipe. To ensure that the pipe is constantly filled with water, you need to install a check valve and then a filter.

- The second end of the pipe, through pre-laid trenches, is led directly to the house’s water supply.

Note: To avoid installation errors, before laying pipes in trenches, it is advisable to calculate the length of the pipe in advance. To do this, you need to take into account the number of bends and the thickness of the foundation.

Water connection

As a rule, the pumping station is connected to the water supply if there is not enough pressure for the heating equipment.

In order to connect the system to the water supply you need:

- The water pipe must be disconnected at a certain point.

- The end of the pipe that comes from the central line is connected to the storage tank.

- The pipe from the tank is connected to the pump inlet, and the pipe that is connected to its outlet goes to the pipe that leads to the house.

- Laying electrical wiring.

- Equipment adjustment.

Check valve

The check valve is considered the most important element in the water supply system. Its main purpose is to prevent leakage.

The check valve is considered the most important element in the water supply system. Its main purpose is to prevent leakage.

In order for the system to work continuously, it must always be filled with water. A check valve prevents water from flowing out of the system by allowing water to flow in only one direction.

This element consists of a spring and a locking element, which are located in the cylinder. As a rule, such an element is placed either in the area in front of the station or at the inlet of the suction pipe. The presence of a check valve allows you to avoid filling the station with water before each operation.

It is better to install the check valve in a vertical position (the arrow on the body should point upward). This will increase the service life of the element.

Of course, it can also be installed horizontally, only then during operation will dirt settle on its walls, which can lead to clogging.

Correct harness

Pumping station piping is the connection of pumping supply to the pipeline and other components.

Pumping station piping is the connection of pumping supply to the pipeline and other components.

This is done as follows:

- Install the system on a horizontal plane.

- The station is connected to the pipeline through a vibration isolator. It blocks vibration when the system is operating.

- Shut-off valves are then secured to allow the pump to be shut off in the event of repairs.

- Installing a strainer on the wicking line.

- For ease of use of the system, it is recommended to install pressure gauges.

- Installation of check valves.

Launch

Before starting the system, it is necessary to check the serviceability and compliance of all elements and adjust the air pressure in the accumulator.

Before starting the system, it is necessary to check the serviceability and compliance of all elements and adjust the air pressure in the accumulator.

After this, the pumping station and suction line must be filled with water (this is done through a special hole in the pump).

Then it must be connected to the electrical network for a smooth start and the pressure and automation checked.

The station should not be started very often, otherwise the engine will overheat. The rate of starts is up to 20 times in one hour (the exact figure must be indicated in the technical data sheet of the system). Then, during operation, it is necessary to control the air pressure in the accumulator (1.5 atmospheres).

Living outside the city, temporarily or permanently, is pleasant, but there are some difficulties in it. After all, not every holiday village has centralized communications. Residents of cottages and private houses quite often have to improve their living conditions on their own.

One of the important points of a comfortable life is the constant availability of water. A pumping station can help with this, which is quite easy to install yourself.

Peculiarities

The pumping station is capable of supplying water to the water supply system of the house, as well as automatically maintaining a given pressure in it. Due to this, you can make the water supply network extensive, making it easier to connect various household appliances to it, for example, a boiler, shower, washing machine, and so on.

The pumping station consists of a pump, a hydraulic accumulator, automation, a filter, and pipelines. A well or borehole is suitable as a source for water intake. You can use water from open reservoirs or other reservoirs. If water is taken from a river, lake or pond, it must be used only for household needs or irrigation. It is better to submit water from a well or borehole for testing, the results of which will show whether it is domestic or drinking.

Basically, in the areas, the depth of the wells is about 20 meters, which is the optimal value for installing automatic equipment. These parameters allow water to be delivered to distribution points without any additional equipment.

The pumping station operates in cycles, each of which is divided into two stages. When the pump is turned on, water rises from the source, filling the system and hydraulic tank. This happens until the pressure exceeds the upper limit. As soon as this happens, the pressure switch turns off the pump and the water stops flowing.

When opening taps or using water-consuming equipment, water flows from the accumulator tank. The fluid from the hydraulic tank will be consumed until it reaches the lower limit. The pump then turns on again and lifts water into the hydraulic tank.

It is necessary to ensure that the number of cycles per hour does not exceed the maximum permissible number of starts for the pump being used.

The advantages of the pumping station are obvious:

- provides autonomous water supply in the house;

- allows you to increase the efficiency of the water supply system;

- allows for safer operation of equipment and pipelines;

- allows you to make a certain supply of water and supply it, even if the power supply is turned off;

- provides stable water pressure and maintains constant pressure;

- increases the service life of devices and household appliances connected to the water supply system;

- reduces energy costs and equipment wear;

- makes it possible to choose a location for installing the unit;

- has compact dimensions and light weight;

- easy to install.

How to choose?

A pumping station for a cottage or private home must cope with its functions, so it should be chosen based on your needs. First of all, you should pay attention to a number of the following criteria.

Station technical characteristics

Moreover, the performance of the device is of greatest importance. It is best to opt for a pumping station, which provides water pressure from a well that satisfies all the needs in the house and in the area around the house.

For a normal life of four people, a device with medium or low power is suitable. As a rule, such units are equipped with a 20-liter hydraulic accumulator. Such stations supply water from a well at a rate of 2-4 cubic meters per hour and provide a pressure of 45 meters or more. It is also worth considering the size of the station, the water level when the pump is running and off, the type of filter, and the width of the pipe.

Features of a well

The finished pumping station is an installation with a surface pump that draws water from the well by vacuum. In this case, the ejector can be present in the pump design or be remote and must be located in the well. However, if you assemble and install the pumping station yourself, you can use a borehole or submersible pump. This is especially true if it is already in stock.

Pumping stations with a built-in ejector allow you to lift water only from a depth of no more than 8 meters. However, they provide good pressure, which exceeds 40 meters. Such installations are not afraid of air penetration, so they do not need to be filled with water before starting work. They calmly pump air first, and then water.

Among the positive differences we can also note high reliability and performance. Of course, there are also disadvantages. One of them is loud noise, so such stations are installed in the house, exclusively in utility rooms with good sound insulation.

Stations with an external ejector are necessary for collecting water from a depth of 20 meters or more. In this case, the ejector is placed in a well or borehole, becoming part of the intake unit. Pressure and suction (vacuum) hoses go to it from the installation. Through the pressure hose, water enters the ejector and a vacuum area is formed in the suction chamber, and through the suction hose the water rises up from the well.

Such stations are characterized by low noise levels and low energy consumption. However, the efficiency of such devices does not exceed 40 percent.

Pumping stations with a submersible pump are also practically silent. They can draw water from any depth and even at a significant distance from the water source from the building. At the same time, they are not afraid of air leaks and small leaks in the pipeline. However, clean water is important to them, which means they will need a powerful filtration system and regular cleaning. Among the disadvantages, it is also worth noting the high cost of such pumps and possible difficulties during repair and maintenance.

Installation diagrams

Before installation, it is necessary to select a location that is optimal for the pumping station.

In this case, it is necessary to take into account:

- distance of the station from the well or well;

- temperature and humidity in the place where the pump will be installed;

- availability of free space for repair and maintenance of the device;

- possibility of soundproofing the room.

Once the installation site for the station has been selected, its installation begins.

There are usually no difficulties when installing a finished pumping station.

- As a rule, preparatory work is carried out first. They consist in making a solid base for the pumping device, for example, from concrete and brick or wood. At the same time, it must have a flat surface. You can also use a special metal bracket.

- When the pump is running, it vibrates quite strongly, as a result, leaks can form at the pipe connections. To reduce vibration and its destructive effect, it is necessary to place a rubber mat or pads under the pump supports. You can also secure the legs more securely using anchor bolts.

- In order for the pumping station to operate without interruption, it is necessary to ensure a constant supply of water from the source. When using water all year round, care should be taken to protect it from freezing. To do this, a trench is dug from the well or caisson of the well to the foundation of the house, into which a pipeline will then be laid, preferably with a diameter of 32 millimeters. It is imperative that the trench runs straight, without bends or turns that lead to a decrease in pressure.

- Pipes must be buried below the level to which the soil freezes in the area. Also, when forming a trench, it is necessary to take into account the slope towards the water intake, so that during the conservation period water is drained from the pipeline. If groundwater is located close, it is necessary to lay the pipeline above its critical level. However, the pipes must be insulated and a heating cable must be used.

- If the pipeline must be run above ground level, it is necessary to organize good thermal insulation and heating. In this case, basalt-based mineral wool can be used as a thermal insulation material.

- The water intake unit in the station with a built-in ejector and surface pump is assembled by connecting a metal mesh and a check valve to the outside of the polypropylene pipe. The mesh in this case is a coarse filter, and a check valve is necessary to ensure that the pipes are steadily filled with water. The valve can be fixed using a coupling having an external thread. If a submersible (well) pump is used, only a check valve and a pipe are needed, and a coarse filter is already included in its design.

- The pump has considerable weight, so it must be suspended on a strong cable. When lowering the water intake unit in a device with a surface pump, it must be taken into account that the minimum distance from the bottom of the source to it must be at least 1 meter. For a submersible pump, this distance is 0.5 meters. It is also necessary to take into account changes in the level of the water surface throughout the year, for example, in summer it usually becomes lower.

- When the pipeline is connected to the pump, a hydraulic accumulator and a control unit are installed. It is best to connect them using a five-pin fitting, which is mounted in the pressure pipeline in a convenient place. A pressure gauge and pressure switch are screwed into it, and a hydraulic accumulator is connected to the side entrance of the fitting.

- When installing the surface elements of the station, it is necessary to take into account that all additional devices are best installed through check valves or ball valves with an American connection. This is necessary in order to easily remove devices when replacing or repairing, without having to drain the water from the system.

- Of course, it is recommended to provide for the possibility of draining water from the system in advance. To do this, it is necessary to form a branch in the pipeline by installing a tee with a drain valve connected to it. In this case, a coarse filter should be installed on the supply pipeline, and a fine filter should be installed on the pressure pipe.

- Next, consumers are connected to the pumping station. As a rule, the very first one is the water distribution collector.

- Before starting the pumping station, it is necessary to take into account that the pump’s electric motor has a lot of power, so it is better to allocate its own power supply line for the entire structure, make grounding, and also install a voltage stabilizer.

- During installation, you should check the pressure of the air chamber of the hydraulic accumulator. Its value should be 10 percent lower than the pump activation pressure. This setting is done in operating mode. As for the preliminary values, they should be for a hydraulic tank with a capacity of 20-30 liters - from 1.4 to 1.7 bar, and for a capacity of 50-100 liters - from 1.7 to 1.9 bar.

- Before starting the installation with a surface pump for the first time, it is necessary to fill the working part of the system with water. This is done by unscrewing the plug from the filler hole, which is located at the top of the pump. If the pipeline is equipped with a fill funnel, then you can use it. Water is poured in until it starts to flow out. After this, you must close the valve (hole) tightly.

- When starting, the pump must be connected to the electrical network. The remaining air trapped in the funnel is removed by slightly opening the valve of the pipeline filler funnel.

- After turning on the device, water should flow from the outlet of the pressure pipeline or open water tap within two to three minutes. If water does not flow, the pump is turned off and water is added to the system, and then turned on again. When the equipment has been successfully launched, it is necessary to “break in” it, and then adjust the settings of the pressure switch and valve body.

How to assemble?

To assemble a pumping station yourself, you first need to understand what it is and how it works. You should also foresee the level of intensity of water use in advance.

Main functional units of the station:

- a centrifugal pump that lifts and transports water into the house;

- a hydraulic accumulator that softens hydraulic shock;

- pressure switch;

- an electric motor connected to a pump and a pressure switch;

- pressure gauge, allows you to determine the pressure;

- water intake system with check valve;

- the main line that connects the water intake and the pump.

A pressure switch allows you to control its level in the system. For example, when the pressure decreases compared to a certain parameter, the engine starts, and if it increases, it turns off. Using a pressure gauge you can adjust the pressure. The most essential element is the hydraulic accumulator. Sometimes in pumping stations a storage tank is used instead, but this design is outdated due to a large number of shortcomings.

Stations with hydraulic accumulators are more reliable and practical. In addition, they are small in size, which simplifies installation.

How to install?

Do-it-yourself pumping station installation in a house is often carried out in a heated room. The most ideal option would be a boiler room with good sound insulation. You can, of course, install it in the corridor, hallway, pantry or bathroom. The main thing is away from the bedrooms.

Often a basement or ground floor is chosen for the location of the pumping station. However, this is provided that they are heat, sound and waterproof. You can also install it in a special box, which is located in the underground and has a hatch to provide access to the equipment.

To install the station in a well, a specially equipped platform is used. It must necessarily be lower than the freezing level. At the same time, it is necessary to insulate the well itself from above. This scheme makes access to the station somewhat difficult.

You can also install a station in the well caisson. To do this, a room is built around the well, which is buried to a level lower than the freezing point of the soil. The caisson must be closed and insulated at the surface of the earth. It is enough to leave a small hatch necessary for maintenance.

Even in the very recent past, a private house was inferior to apartments in terms of comfort: you had to fetch water from the street, wash dishes in a bowl, and there was no question of a shower at all. But times have changed and modern equipment, if there is a water intake point, makes it possible to arrange a water supply in any structure. In this material you will find answers to questions if you are interested in the water supply scheme for a private home and types of water supply.

Types of water supply systems for a private home

Home water supply systems are classified depending on the source from which water will be taken for supply to the structure.

The arrangement of such a system is possible if a water main runs near the suburban area. To make a connection, you need to contact the relevant authorities, who will carry out the work in accordance with the standards.

It is worth noting the main features of the centralized system:

- There is an unpleasant odor in the water or chlorine.

- Poor pressure or its complete absence.

- In the event of an accident on the main line, you can be left without water in your home for a long time.

The only significant advantage of the system is that it works without electricity.

Well

The advantages of such a water source for home water supply:

- Service life: more than 50 years.

- Relatively affordable cost of arrangement.

- You can dig a well yourself.

- If there is no power supply, there is access to water (it can be collected with a regular bucket).

It is worth considering the requirements for the well:

- The water level is 4-15 m.

- The water can be eaten.

- The presence of an aquifer that will be sufficient to meet the needs of water intake points.

Before you finally decide to dig a well, visit your neighbors who already have such a source of water in their yard and find out about its quality.

Well

Wells can be artesian or sand wells. When choosing between these water sources, you need to consider the following points:

- A well “on sand” will last up to 7 years, and if you get to an underground river – up to 20. An artesian well can provide water supply for many years.

- When setting up a well in the sand, it is better to use hand-held drilling equipment: the likelihood of getting to a high-quality source of water in this case will be higher, but the machine will simply drill to the specified depth.

- The cost of an artesian well is higher than usual, but the quality of water, natural pressure and large reserves justify the overpayment.

Planning the plumbing system

This option was preferred by many home owners and is considered to be optimal. It’s worth noting right away that the pumping station has some disadvantages:

- Complete dependence on electricity. This can be solved by installing a generator or uninterruptible power supply.

- High noise level during operation. You just need to install it away from living rooms, soundproof the room, or choose the basement for the equipment location.

The optimal place to install a pumping station is a basement or a separate room specially built for such purposes. It is worth considering that for good operation of the equipment, certain conditions must be provided: good thermal and waterproofing, a flat floor, etc.

Another way to install a pumping station is in a caisson. In this case, special attention is paid to the level of humidity - the equipment does not tolerate moisture and must be installed in a dry place.

Some features of the pumping station:

- The end of the pipe where the water intake begins must be equipped with a check valve.

- The wiring is installed very carefully. When performing such work, you should follow the rules for installing electrical networks in rooms with high humidity levels.

- There is no need to install additional tanks to install a water supply system. Water supply occurs according to the following scheme: well – station – water intake point.

Main components of the station:

- A pump that allows water to move through the system.

- A hydraulic accumulator is a reservoir that stores water and acts as a compensator for insufficient pressure.

- Pipe system.

- Automatic pressure switch and pressure gauge.

- Dry running relay.

- System components responsible for automatic control.

It is optimal to use a pumping station when supplying water to a house from a well.

This system is convenient for constant use and supplies water to the mixer immediately after opening it.

Water tank

In this case, to ensure the supply of water to the house, the principle of a water tower is used: a special tank of a certain capacity is installed above the water intake points (in the attic), and the water moves through the system by gravity. It is immediately worth highlighting the disadvantages of such a system:

- Lack of constant and strong pressure.

- There is a risk of flooding of the structure.

- You need to constantly monitor the water level in the tank.

- A large container of water can cause damage to the structure of the house.

Due to inefficiency and a minimal level of automation, the water tank has become used quite rarely, so it makes no sense to consider its arrangement in detail.

Borehole pump paired with a hydropneumatic tank

This solution is used in cases where a conventional pumping station cannot cope with the assigned tasks: the water level is quite large (more than 50 meters). Also, a well pump is capable of supplying water to a height of up to 30 m and at the same time there will be the same pressure at all water intake points.

A pump with a hydraulic accumulator can be called a modification of a pumping station, in which, instead of a conventional device for transporting water, a deep one is used, installed in close proximity to the water source. In this case, the tank is installed in a caisson or basement.

Main components of the system:

Components of a water supply system with a well pumpThe scheme is selected solely based on the needs of a particular family and material capabilities. If the allocated budget is enough to drill an artesian well and install a deep-well pump, then this choice will allow you to forget about problems with water supply for a long time.