Advantages and disadvantages of composite reinforcement. Pros and cons of composite fiberglass reinforcement Advantages and disadvantages of fiberglass products

Fiberglass reinforcement, which appeared on the construction market quite recently, is already an excellent replacement for traditional steel rods. It has a number of characteristics that become benefits when using it.

General properties

If we talk about the design of such reinforcement, we can say that it consists of a non-metallic rod with a layer of fiberglass on the outside. Depending on the diameter, the rods can be different; their sizes vary from 4 to 18 mm. If the diameter is less than 10 mm, the reinforcement is supplied in coils; if it is larger, then it can be purchased in the form of rods with a length reaching 12 meters.

Fiberglass reinforcement, which is presented in the catalog website, has many properties that become its distinctive features compared to other types of materials:

- Light weight, which is 9 times less than metal analogues.

- Resistant to corrosion, as well as alkaline, salty and acidic environments.

- A lower proportion of the possibility of cold bridges occurring than when using metal fittings due to low thermal conductivity.

- Duration of operation.

- Lower shipping costs.

- Ease of use and elimination of the use of special equipment for cutting metal.

- Dielectric properties that allow it to not conduct electricity.

- Environmental Safety.

Manufacturing nuances

The production process of fiberglass reinforcement can be fully automated, which allows this material to be produced in both large and small enterprises. Initially, the raw material, which is aluminoborsilicate glass, is melted in special furnaces until the required degree of ductility is obtained. Thin threads, each 10–20 microns thick, are drawn from the finished mass, onto which an oil-based composition is applied. Bundles are formed from the threads, which will serve as the basis for the fiberglass rod, forming its strength and other characteristics. After this, the prepared threads are fed to the production line, where they are formed into reinforcement with different diameters.

Technical data

- not less than 800 MPa and not more than 1200 MPa;

- elastic modulus – 55000 MPa;

- relative elongation rate – 2.2%;

- winding pitch – 15 mm;

- weight of one profile – from 0.02 to 0.42 kg per 1 linear meter;

- Temperature limit for use is 60 degrees Celsius.

Areas of application

Fiberglass reinforcement is now used quite widely. It is usually used to create reinforcement for an elastic foundation, that is, to form a reinforcement frame in the foundations of buildings. In addition, reinforcement with composite reinforcement is also carried out for drainage pipes and other parts. In construction, fiberglass reinforcement makes it possible to improve the quality of walls and create flexible connections between brickwork. In addition, fiberglass reinforcement is used to strengthen embankments, reinforce road surfaces and other purposes.

Individuals engaged in construction on their suburban plots have already found application for fiberglass reinforcement in other areas. For example, an interesting experience is the formation of arcs for greenhouses from coils of reinforcement. As a result, if desired, you can get a reliable structure that will not be subject to corrosion and will last for more than one year.

Types of fiberglass reinforcement

On the company's website you can purchase various types of fiberglass reinforcement, both wholesale and retail. In the presented assortment you can find fiberglass reinforcement:

- distribution;

- installation room;

- working;

- intended for the formation of reinforced frames for concrete structures.

All varieties presented are of high quality, and their cost is not as high as with alternative purchase options. In addition, we offer fast delivery in a convenient way for the client to any region. We have our own delivery service in Moscow and the Moscow region, which guarantees a simple and safe transportation process for any quantity of purchased material.

If any questions arise, the buyer can always contact qualified specialists who can easily tell you what type of fiberglass reinforcement to choose for certain conditions and calculate the cost of the order in full.

We begin processing the order immediately after it is received, which guarantees the shortest possible time. This is very convenient for those buyers who are already in the process of construction and simply cannot wait a long time.

If you need high-quality fiberglass reinforcement at an affordable price for any purpose, then contacting the site will be the best option.

Which appeared on the construction market relatively recently, has both advantages and disadvantages, which the consumer must be aware of. Despite the assurances of manufacturers that this product is a complete replacement for metal fittings, its use cannot be considered justified in all situations.

What is fiberglass reinforcement

The so-called composite reinforcement is a fiberglass rod around which a carbon fiber thread is wound, which serves not only to strengthen the structure of such a product, but also to ensure its reliable adhesion to the concrete mortar. This type of fittings has both pros and cons, and its use should be approached very carefully.

Plastic clamps serve as elements for fixing carbon fiber reinforcement bars to each other. Conveniently, connecting the elements of such fittings does not require the use of welding, which is undoubtedly a big plus.

When assessing the feasibility of using fiberglass reinforcement, it is necessary to consider all the pros and cons of its use in individual situations. This approach will ensure the high efficiency of this material as a means of strengthening building structures for various purposes.

If you do not take into account the characteristics of fiberglass reinforcement and do not compare them with the parameters of similar products made of metal, you can cause serious damage to the future building structure or finishing elements. That is why, before you start choosing elements for reinforcing concrete structures, you should understand in which cases the use of certain products is more appropriate.

Main advantages

Among the advantages of carbon fiber reinforcement, it is worth highlighting the following.

- An important advantage of fiberglass reinforcement is its low specific weight, which makes it possible to use it for reinforcing light structures made of cellular concrete and some other building materials. This allows you to significantly reduce the weight of structures that are reinforced with its help. Meanwhile, the weight of a conventional concrete structure when using fiberglass reinforcement will decrease slightly, since the building material itself has an impressive mass.

- Low thermal conductivity is also an advantage of fiberglass reinforcement. When using such reinforcement in concrete structures, no cold bridges are formed (which cannot be said about metal reinforcing elements), which significantly improves their thermal insulation parameters.

- The high flexibility of fiberglass reinforcement allows it to be shipped to the customer in coils, rather than cut into individual rods. Thanks to the compact form of packaging, it is much easier to transport such reinforcement, for which you can use the trunk of any passenger car, and this seriously reduces the cost of delivering the material to the construction site. The use of reinforcing elements, which are shipped not as cut rods, but in coils, also makes it possible to reduce material costs by reducing the number of overlaps. This has a positive effect on both the strength characteristics of the future concrete structure and its cost, which is especially important when performing construction work.

- The advantage of fiberglass reinforcement, such as its durability inside a concrete structure, is considered quite controversial. Metal fittings, being in an isolated state, are also not subject to the negative influence of external factors, which ensures the durability of its use.

- Carbon fiber reinforcement is a dielectric material, which is an advantage of products made from this material. Electrically conductive metal fittings are more susceptible to corrosion, which negatively affects its durability.

- Compared to metal reinforcing elements, fiberglass products are not exposed to chemically active environments. This advantage of fiberglass reinforcement is especially important in cases of construction of buildings in winter, when various salt solutions are added to the concrete, accelerating the hardening process.

- Being a dielectric, carbon fiber reinforcement does not create radio interference inside the building, unlike metal rods. This advantage is important when there are many reinforcing elements in a concrete structure. Otherwise, the use of composite reinforcement will not be a disadvantage, but it will not be so relevant.

Fiberglass reinforcement also has disadvantages, which potential consumers should also be aware of.

Main disadvantages

The disadvantages of fiberglass reinforcement are associated with its following characteristics.

- The disadvantages of fiberglass reinforcement include, in particular, the fact that it cannot withstand high temperatures. At the same time, it is difficult to imagine a situation where a reinforcement cage located inside concrete can be heated to a temperature of 200 degrees.

- The rather high cost is a drawback, given the fact that for the reinforcement of concrete structures it is possible to use fiberglass reinforcement of a smaller diameter in comparison with metal products.

- Carbon fiber reinforcement does not bend well. This drawback limits its use in creating reinforcing frames for concrete structures. Meanwhile, bent sections of the reinforcement frame can be made from steel elements, and then they can be extended using fiberglass rods.

- Reinforcement made of fiberglass does not withstand fracture loads well, which is very critical for concrete structures. Accordingly, their reinforcing frame must successfully withstand such loads, which reinforcement made of composite materials cannot boast of.

- Unlike metal reinforcement frames, fiberglass products have less rigidity. Because of this drawback, they do not tolerate vibration loads that occur when pouring them using a car mixer. When using this technique, the reinforcement frame is subjected to significant mechanical loads, which can cause its breakage and disruption of the spatial position of its elements, therefore quite high demands are placed on the rigidity of such concrete structures.

Considering the advantages and disadvantages of fiberglass reinforcement, it is difficult to say how much better or worse it is made of metal. In any case, the choice of this material should be approached very reasonably, using it to solve the problems for which it is really intended.

Areas of application of fiberglass reinforcement

Reinforcement made of composite materials, the installation rules of which are easy to learn from the corresponding videos, is used in both capital and private construction. Since capital construction is carried out by qualified specialists who are well acquainted with the nuances and disadvantages of using certain building materials, we will dwell on the features of using such material in the construction of private low-rise buildings.

- Reinforcement made from composite materials is successfully used to strengthen the following types of foundation structures: strip, whose height is greater than the freezing depth of the soil, and slab. The use of carbon fiber reinforcement to strengthen foundations is advisable only in cases where the structure is being built on good soil, where the concrete foundations will not be subject to fracture loads that fiberglass elements simply cannot withstand.

- Using fiberglass reinforcement, they strengthen walls whose masonry is made of brick, gas silicate and other blocks. It should be noted that, as a connecting element of walls, composite reinforcement is very popular among private developers, who use it not only to strengthen the masonry of load-bearing structures, but also to ensure their connection with facing partitions.

- This material is also actively used to bind elements of multilayer panels. The structure of the latter includes a layer of insulation and concrete elements, which are connected to each other using fiberglass reinforcement.

- Due to the fact that the type of reinforcement in question does not have such a disadvantage as susceptibility to corrosion, it is often used to strengthen various hydraulic structures (for example, dams and pools).

- In cases where it is necessary to effectively increase the rigidity of laminated timber beams, they are also strengthened with fiberglass reinforcement.

- This material is also used in road construction: it is used to strengthen the asphalt layer, which is subjected to increased loads during its operation.

Summarizing all of the above, it should be noted that fiberglass reinforcement can be used quite effectively, if we take into account its disadvantages and associated limitations, which are specified by the manufacturer.

Can fiberglass reinforcement replace metal counterparts?

Despite the fact that reinforcement made from composite materials is a fairly new material on the construction market, you can already find many recommendations (and even videos) on its use. Considering these recommendations, we can conclude that it is best to use fiberglass reinforcement to strengthen walls built from bricks and building blocks, as well as to connect load-bearing walls with interior partitions.

Reinforcement is an integral process of creating reinforced concrete structures or products. In some cases, steel is contraindicated, so in the middle of the last century a replacement was developed - composite reinforcement.

Concrete is a strong, but absolutely non-plastic material. It has excellent resistance to compressive loads and does not withstand tensile pressure. Therefore, an improperly formed foundation begins to quickly crack, crumble, and requires restoration work. To strengthen and strengthen the structure, a skeleton of reinforcing rods is used, which evenly distributes loads and increases the service life of the frame.

Fiberglass composite reinforcement for foundations is made from a mixture of:

1. reinforcing component - glass staple fiber, which takes on mechanical stress;

2. polymer binders that provide good adhesion to concrete, uniform pressure distribution and protection from external aggressive environments. Most often it is a multicomponent epoxy resin with special additives, hardeners and accelerators.

The ratio of composite elements is approximately 75:25. There are practically no uniform standards for the production and use of this type of product, and therefore each enterprise develops its own recipe and recommendations on how best to calculate the minimum required amount of fiberglass for the foundation, walls, columns, slabs, and so on.

There are 2 types of fiberglass reinforcement available:

- A periodic profile resembling a spiral winding. Achieved by wrapping a fiberglass rod around the main rod. The product is covered with a layer of binder on top, which protects the reinforcing component from external influences.

- Conditionally smooth. The surface is sprinkled with fine sand, which promotes better adhesion of the material to concrete or other type of mortar. The cost of this type of product is approximately 15-18% higher than its corrugated counterpart.

The fittings are produced in rods with a diameter of 4-18 mm. It can be purchased packaged in coils of 50-100 linear meters or in rods 6 m long.

The formation pattern of the spatial frame is similar to the metal one. The goal is to strengthen the foundation, floor or slab in the most vulnerable areas. Therefore, horizontal rows are located closer to the surface with a minimum interval between them of up to 50 cm, and transverse distribution and vertical support elements are installed in the form of a frame with a pitch of 30-80 cm.

The use of reinforcement is not limited only to supporting structures, such as foundations, columns, power line supports, lighting poles, and the like. Fiberglass is used:

- For the construction of septic tanks, roads, sidewalks.

- In the production of shaped products.

- When forming industrial floors, decking, fencing, bridge structures.

- When constructing multi-layer brickwork or monolithic walls, partitions, ceilings.

Fiberglass products are even used in the construction of log houses from rounded or debarked logs. The fact is that with some mistakes (damp timber, changes in design without agreement with the architect), in places of greatest load the structure begins to sag or bend. The use of metal products indoors is undesirable, so composite fittings come to the rescue.

Pros and cons of fiberglass

The weight of composite reinforcing products is almost 4 times less than its steel counterpart. The foundation will weigh significantly less, which means the load on the ground will be reduced. In addition, the fittings have the following advantages:

1. Almost complete inertness to aggressive media, including alkali released by concrete, solvents, sea water and the like. Thanks to this property, fiberglass can be used in the construction of barriers for hydroelectric power stations, piers, jetties and other objects.

2. Complete radio transparency and absolute inertness to magnetic fields. Composite reinforcement is perfect for the construction of buildings (foundations, walls and ceilings), which are supposed to house laboratories, special-purpose premises, and the like.

3. The thermal expansion index is close to that of concrete, so there will be no problems with temperature changes.

4. Easy to transport. The fittings can even be transported in the trunk of a car.

Unscrupulous sellers also try to attribute cost to the advantages of their products, but this is rather a disadvantage. The price of rolled metal with a diameter of 8 mm is 8 rubles/linear meter, and fiberglass of the same section is 18.

Price of glass composite in Moscow and the Moscow region:

Among the disadvantages we also note:

1. Instability of glass-composite reinforcement to high temperatures.

2. When loaded, the rod begins to stretch, although it should, on the contrary, restrain the deformation process. For comparison: the elasticity index of steel is 200,000 MPa, the same index of fiberglass is 55,000.

3. When pouring concrete into the formwork, the composite material bends and deforms. This makes it difficult to form an even foundation.

4. Wire or plastic clamp is used for tying; welding is not permitted.

5. Curvilinear structures, as well as corners, column outlet areas have to be formed using metal reinforcement; fiberglass is absolutely not suitable.

6. There is no single package of regulatory documents and standards, so it is difficult for buyers to choose a truly high-quality product. It is even more difficult for designers who must recalculate loads.

Due to a large number of shortcomings, the composite is not widely used in construction, both industrial and civil.

Reviews from people

“Steel and composite reinforcement are offered on the market nearby. The seller gave me brochures and flyers for the latter to read. I decided to take it as a test for the foundation for a frame bathhouse. I really regretted that I didn’t look for additional information about this product or read the reviews. The foundation stood for a couple of months, then cracks appeared, and the question of its repair arose. I will strengthen it with metal strips and hope that things won’t get worse.”

“Steel and composite reinforcement are offered on the market nearby. The seller gave me brochures and flyers for the latter to read. I decided to take it as a test for the foundation for a frame bathhouse. I really regretted that I didn’t look for additional information about this product or read the reviews. The foundation stood for a couple of months, then cracks appeared, and the question of its repair arose. I will strengthen it with metal strips and hope that things won’t get worse.”

Victor, Samara.

“Sellers claim that fiberglass helps save money. From my own experience I was convinced that they were lying. Firstly, you have to make a recalculation: if metal reinforcement with a diameter of 8 mm is required, then fiberglass must be taken with a cross-section of 14 or 16 mm, and its price is 2 times higher. The plastic clamps that come with the ligaments do not inspire confidence at all.”

“Sellers claim that fiberglass helps save money. From my own experience I was convinced that they were lying. Firstly, you have to make a recalculation: if metal reinforcement with a diameter of 8 mm is required, then fiberglass must be taken with a cross-section of 14 or 16 mm, and its price is 2 times higher. The plastic clamps that come with the ligaments do not inspire confidence at all.”

Egor, Kazan.

“I built a house from expanded clay concrete blocks with ready-made front finishing. According to the technology, a reinforcing belt needs to be laid every 4 rows. I bought 3 rolls of fiberglass at the market for these purposes and took them to the construction site in my car, since the load is compact and weighs little, and also does not rust.”

“I built a house from expanded clay concrete blocks with ready-made front finishing. According to the technology, a reinforcing belt needs to be laid every 4 rows. I bought 3 rolls of fiberglass at the market for these purposes and took them to the construction site in my car, since the load is compact and weighs little, and also does not rust.”

Vladimir Vorontsov, Kaluga.

“I used fiberglass composite rods to strengthen the walls made of foam blocks. It’s easy to work with, cut, and attach. Easy to transport, although a little expensive.”

“I used fiberglass composite rods to strengthen the walls made of foam blocks. It’s easy to work with, cut, and attach. Easy to transport, although a little expensive.”

Pavel Kalinin, Rostov-on-Don.

Developed in the middle of the last century in the USSR, fiberglass reinforcement (abbreviated as ASP or SPA) began to be used on a large scale relatively recently. Fiberglass products have gained popularity due to the reduction in the cost of their production. Light weight, high strength, wide application possibilities and ease of installation have made SPA fittings a good alternative to steel rods. The material is perfect for low-rise construction, construction of coastal fortifications, load-bearing structures of artificial reservoirs, elements of bridges, and power lines.

Fiberglass composite reinforcement (FRC) is a rod made from glass woven thread-like fiber (roving), straight or twisted, bonded with a special composition. These are usually synthetic epoxy resins. Another type is a fiberglass rod wound with carbon filament. After winding, such fiberglass blanks are subjected to polymerization, turning them into a monolithic rod. Fiberglass reinforcement has a diameter of 4 to 32 mm, a thickness of 4 to 8 mm and is packaged in coils. The bay contains 100-150 meters of reinforcement. It is also possible to cut in the factory, when the dimensions are provided by the customer. The strength characteristics of the rod depend on the production technology and binder.

Options for packaging and transportation of ASP.

The material is produced by the drawing method. Fiberglass wound on reels is unwound, impregnated with resins and hardeners. After this, the workpiece is passed through dies. Their purpose is to squeeze out excess resin. There, the future reinforcement is compacted and takes on a characteristic shape with a cylindrical cross-section and a given radius.

After this, a tourniquet is wound in a spiral around the still uncured workpiece. It is necessary for better adhesion to concrete. The material is then baked in an oven, where the process of hardening and polymerization of the binder occurs. From the furnace the rods are sent to a mechanism where they are drawn. Modern plants use tube furnaces for polymerization. They also remove volatile substances. The finished products are wound into coils or rods are cut to the required length (upon customer's prior order). Afterwards the products are sent to the warehouse. The client can also order reinforcement with a given bending angle.

Purpose and scope

Fiberglass reinforcement is used in various branches of industrial and private construction, for conventional and prestressed reinforcement of building structures and elements, the operation of which takes place in environments with varying degrees of aggressive influence. The most famous examples of use.

- Reinforcement of block, brick walls and walls made of gas silicate blocks. Fiberglass reinforcement showed very good results when reinforcing these structures. Main advantages: cost savings and lighter structures.

- As a binder of concrete elements between which insulation is located. SPA improves the adhesion of concrete elements.

- To strengthen load-bearing structural elements that are exposed to factors that cause corrosion (artificial reservoirs, bridges, shoreline fortifications of fresh and salty natural reservoirs). Unlike metal rods, fiberglass rods are not subject to corrosion.

- For reinforcing laminated wood structures. The use of SPA reinforcement can significantly increase the strength of laminated wood beams and increase the rigidity of the structure.

- It is possible to use strip buried foundations for low-rise buildings in the construction if they are located on hard, motionless soils. Deepening is carried out below the soil freezing level.

- To increase the rigidity of floors in residential buildings and industrial complexes.

- To increase the strength and durability of paths and road surfaces.

Scope of application of fiberglass reinforcement.

Properties of fiberglass reinforcement

To understand the pros and cons of fiberglass reinforcement, you need to know its properties. A description of the advantages of fiberglass reinforcement is given below.

- The corrosion resistance of fiberglass rods is almost 10 times higher than that of traditional metal rods. Glass composite products practically do not react with alkalis, salt solutions and acids.

- The thermal conductivity coefficient is 0.35 W/m C versus 46 W/m C for steel bars, which eliminates the appearance of cold bridges and significantly reduces heat loss.

- The connection of glass composite rods is made with plastic clamps, knitting wire and appropriate clamps without a welding machine.

- Fiberglass reinforcement is an excellent dielectric. This property has been used since the middle of the last century in the construction of power transmission line elements, railway bridges and other structures where the electrically conductive properties of steel negatively affect the operation of devices and the integrity of the structure.

- The weight of 1 meter of high-quality glass-composite reinforcement is 4 times less than a meter of steel rod of equal diameter with equal tensile strength. This makes it possible to reduce the weight of the structure by 7-9 times.

- Lower cost compared to analogues.

- Possibility of seamless installation.

- The value of the coefficient of thermal expansion is close to the coefficient of thermal expansion of concrete, which practically eliminates the occurrence of cracks due to temperature changes.

- Wide temperature range at which the material can be used: from – 60 C to +90 C.

- The declared service life is 50-80 years.

In some cases, fiberglass reinforcement can successfully replace steel, but it has a number of disadvantages that must be taken into account at the design stage. The main disadvantages of fiberglass reinforcement.

- Low heat resistance. The binder ignites at a temperature of 200 C, which is not significant in a private home, but is unacceptable in industrial facilities where increased fire resistance requirements are imposed on structures.

- The modulus of elasticity is only 56,000 MPa (for steel reinforcing wire it is about 200,000 MPa).

- Inability to independently bend the rod at the desired angle. Curved rods are manufactured at the factory according to individual orders.

- The strength of textolite products decreases over time.

- Fiberglass reinforcement has low fracture strength, which only worsens over time.

- Impossibility of creating a solid, rigid frame.

Types of fittings

The use of fiberglass reinforcement in construction requires familiarization with the types of this material. According to purpose, the material is divided into products:

- for installation work;

- working;

- distribution;

- for reinforcing structural elements made of concrete.

According to the method of application, ASP is divided into:

- cut rods;

- reinforcing mesh;

- reinforcement frames.

By profile shape:

- smooth;

- corrugated.

Profile shape of fiberglass reinforcement.

Comparative characteristics of SPA and steel reinforcement

In order to choose fiberglass or steel reinforcement, it is necessary to clearly compare the two types. Comparative characteristics of steel and fiberglass reinforcement are given in the table.

| Material | SPA | Steel |

|---|---|---|

| Tensile strength, MPa | 480-1600 | 480 -690 |

| Relative extension, % | 2,2 | 25 |

| Modulus of elasticity, MPa | 56 000 | 200 000 |

| Corrosion resistance | Corrosion resistant | Depending on the type of steel, it is susceptible to corrosion to a greater or lesser extent. |

| Thermal conductivity coefficient W/m C | 0,35 | 46 |

| Thermal expansion coefficient in the longitudinal direction, x10 -6/C | 6-10 | 11,7 |

| Coefficient of thermal expansion in the transverse direction, x10-6/C | 21-23 | 11,7 |

| Electrical conductivity | Dielectric | Conductor |

| Fracture strength | Low | High |

| Optimal temperature range | from -60 C to +90 C | Lower limit from -196 C to -40 C; upper limit from 350 C to 750 C |

| Service life, years | up to 50 | 80-100 |

| Connection method | clamps, clamps, binding wire | binding wire, welding |

| Possibility of bending rods under construction conditions | No | There is |

| Radio transparency | Yes | No |

| Environmental friendliness | Low toxic material, safety class 4 | Non-toxic |

SPA installation features

The properties and technical characteristics of SPA make the material almost ideal for building a house with your own hands. In order for the house to be durable and last for several generations of the family, it is important to correctly install fiberglass reinforcement, taking into account its disadvantages.

Horizontal reinforcement of the foundation

Laying SPA to reinforce the foundation is carried out after installing the formwork and preparing the area. After this, a longitudinal layer of rods is laid. To do this, take rods with a diameter of 8 mm. A transverse one is laid on it. To do this, take a 6 mm SPA. These layers form a grid. The connection nodes are fixed with tightening clamps or knitting wire, the diameter of which is 1 mm, in 2 belts. Connections are made using, which you can buy or make yourself using thick wire. For large volumes of work, it is recommended to use an electrically driven tying machine.

The edges of the mesh of rods should be 5 cm from the formwork. The required location can be achieved using clamps or ordinary bricks. When the mesh is ready and positioned correctly, pour the concrete mixture. Caution must be exercised here. The reinforcement for the ASP foundation does not have the same hardness as steel. If poured carelessly, it may bend or move from the specified position. If the rods move, it will be extremely difficult to correct the situation after pouring.

To obtain a solid foundation without voids, the poured concrete mixture is compacted with a construction vibrator.

How to avoid problems?

The main problems associated with the use of glass fiber rods are poor quality/defective material and poor engineering design calculations. Problems can arise in the construction of a house if the characteristics of the fiberglass reinforcement used are not taken into account.

Accurate calculations, careful execution of work, and strict adherence to the manufacturer’s recommendations for the selection and installation of materials will help you avoid problems during and after construction.

It is possible to check the quality of a product before purchasing only visually. To do this, you should pay attention to the following points.

- Manufacturer. If the product is not purchased from a factory, you must request documentation for the product confirming its quality and factory (not artisanal) type of production.

- Color. Uniform color throughout the entire bar indicates quality. An unevenly colored product means that the production technology was violated.

- Brown color indicates the substance is burning out.

- Green indicates insufficient heat treatment.

- The surface of the rod should be free of chips, gouges, cavities and other defects, the spiral winding should be smooth, continuous, with a constant pitch.

- Despite the desire to save money, you need to remember that high-quality fiberglass reinforcement is not sold cheaply. Too low a price indicates low strength and fragility.

The use of fiberglass reinforcement in some cases is advisable instead of metal reinforcement. Sometimes it is permissible to combine metal and fiberglass rods when constructing one structure. In order not to later regret using AKS, you should carefully carry out calculations of future buildings at the design stage. Composite reinforcement is selected similarly to steel, taking into account key parameters: bending strength, tensile strength, etc.

The possibility of using fiberglass rods is assessed based on the mobility and type of soil, fire safety requirements, longitudinal and lateral loads that will affect the structure. For example, on swampy and mobile soils, metal reinforcement is used for reinforcement. Fiberglass reinforcement will simply be broken by ground movements due to its low fracture strength.

Fiberglass reinforcement, which appeared on the domestic market relatively recently, has become a worthy alternative to traditional rods made of metal. Glass reinforcement, as this material is also called, has many unique characteristics that set it apart from other products of similar purpose. Meanwhile, you should approach your choice very carefully.

What is fiberglass reinforcement

Fiberglass reinforcement, if you understand its design features, is a non-metallic rod, on the surface of which a winding of fiberglass is applied. The diameter of the spiral profile of reinforcement made of composite materials can vary in the range of 4–18 mm. If the rod diameter of such reinforcement does not exceed 10 mm, then it is sold to the customer in coils; if it exceeds, then in rods, the length of which can reach up to 12 meters.

For the manufacture of composite reinforcement, various types of reinforcing fillers can be used, depending on this, it is divided into several categories:

- ASK – products made on the basis of fiberglass;

- AUK – carbon composite reinforcing products;

- ACC – reinforcement made of combined composite materials.

In the domestic market, fiberglass reinforcement is most widespread.

Features of the structure

Fiberglass reinforcement is not just a rod made of composite material. It consists of two main parts.

- The inner rod consists of parallel fiberglass fibers connected to each other using a polymer resin. Some manufacturers produce reinforcement, the fibers of the inner trunk of which are not parallel to each other, but are curled into a pigtail. It should be noted that it is the inner rod of the fiberglass reinforcement that forms its strength characteristics.

- The outer layer of a reinforcing bar made of fiberglass can be made in the form of bidirectional winding of fibers of a composite material or in the form of spraying of fine abrasive powder.

The design of fiberglass reinforcement bars, which largely determines their technical and strength characteristics, depends on the imagination of the manufacturers and the manufacturing technologies they use for this material.

Basic properties

Fiberglass reinforcement, according to the results of numerous studies conducted by competent organizations, has a number of characteristics that distinguish it favorably from other materials of similar purpose.

- Fiberglass reinforcement bars have a low weight, which is 9 times less than the weight of similar metal products.

- Fiberglass reinforcement, unlike metal products, is very resistant to corrosion and perfectly withstands acidic, alkaline and salty environments. If we compare the corrosion resistance of such reinforcement with similar properties of steel products, it is 10 times higher.

- The property of fiberglass reinforcement to conduct heat is significantly lower than that of metal products, which minimizes the risk of cold bridges occurring during its use.

- Due to the fact that fiberglass reinforcement is much easier to transport, and its service life is much longer than that of metal, its use is more profitable in financial terms.

- Fiberglass reinforcement is a dielectric material that does not conduct electric current and is absolutely transparent to electromagnetic waves.

- Using such material to create reinforcing structures is much simpler than metal rods; there is no need to use welding equipment or technical devices for cutting metal.

Thanks to its undeniable advantages, fiberglass reinforcement, having appeared relatively recently on the domestic market, has already gained high popularity among both large construction organizations and private developers. However, such fittings also have a number of disadvantages, the most significant of which include:

- fairly low elastic modulus;

- not too high thermal stability.

The low modulus of elasticity of fiberglass reinforcement is a plus in the manufacture of frames to strengthen the foundation, but a big disadvantage if it is used to reinforce floor slabs. If it is necessary to turn to this particular reinforcement in such cases, it is necessary to first carry out careful calculations.

The low thermal stability of fiberglass reinforcement is a more serious drawback that limits its use. Despite the fact that such reinforcement belongs to the category of self-extinguishing materials and is not capable of serving as a source of fire spread when used in concrete structures, at high temperatures it loses its strength characteristics. For this reason, such reinforcement can only be used to strengthen those structures that are not exposed to high temperatures during operation.

Another significant disadvantage of reinforcement made of fiberglass is that over time it loses its strength characteristics. This process is significantly accelerated if it is exposed to alkaline environments. Meanwhile, this disadvantage can be avoided if you use fiberglass reinforcement made with the addition of rare earth metals.

How and from what are fiberglass reinforcement made?

Many people are familiar with fiberglass reinforcement not only from photos on the Internet, but also from practical use in construction, but few people know how it is produced. The technological process for the production of fiberglass reinforcing bars, which is very interesting to watch on video, is easy to automate and can be implemented on the basis of both large and small production enterprises.

To produce such a building material, it is first necessary to prepare the raw material, which is aluminoborsilicate glass. To give the raw material the required degree of ductility, it is melted in special furnaces and threads with a thickness of 10–20 microns are drawn from the resulting mass. The thickness of the resulting threads is so small that if you take them in a photo or video, you won’t be able to see them without enlarging the resulting image. An oil-containing composition is applied to the glass fibers using a special device. Then they are formed into bundles, which are called glass roving. It is these bundles, assembled from many thin threads, that are the basis of fiberglass reinforcement and largely form its technical and strength characteristics.

After the fiberglass strands are prepared, they are fed to the production line, where they are turned into reinforcing bars of various diameters and different lengths. The further technological process, which can be seen from numerous videos on the Internet, is as follows.

- Through special equipment (a creel), the threads are fed to a tensioning device, which simultaneously performs two tasks: it equalizes the tension present in the glass threads, arranges them in a certain sequence, and forms the future reinforcing bar.

- Bundles of threads, on the surface of which an oil-containing composition has previously been applied, are sprayed with hot air, which is necessary not only for drying them, but also for slight heating.

- Bundles of threads heated to the required temperature are lowered into special baths, where they are impregnated with a binder, also heated to a certain temperature.

- Then the bundles of threads are passed through a mechanism, with the help of which the final formation of the reinforcing bar of the required diameter is carried out.

- If reinforcement is manufactured not with a smooth, but with a relief profile, then immediately after leaving the calibration mechanism, bundles of glass fibers are wound onto the main rod.

- To speed up the process of polymerization of binder resins, the finished reinforcing bar is fed into a tunnel kiln, before entering which a layer of fine sand is applied to the bars made without coiling.

- After leaving the furnace, when the fiberglass reinforcement is almost ready, the rods are cooled with running water and submitted for cutting or to a mechanism for winding them into coils.

Thus, the technological process of manufacturing fiberglass reinforcement is not so complicated, as can be judged even from photos or videos of its individual stages. Meanwhile, such a process requires the use of special equipment and strict adherence to all regimes.

In the video below you can more clearly familiarize yourself with the production process of composite glass reinforcement using the example of the operation of the TLKA-2 production line.

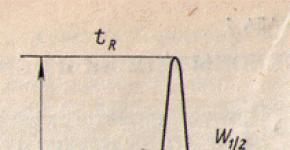

Parameters – weight, diameter, winding pitch

The fittings for the manufacture of which fiberglass is used are characterized by a number of parameters that determine the scope of its application. The most significant include:

- weight of one linear meter of reinforcing bar;

- for products with a relief profile - the pitch of winding fiberglass bundles on their surface;

- diameter of the reinforcing bar.

Today, reinforcement with a relief profile is produced mainly with a winding pitch of 15 mm.

The outer diameter of the reinforcing bar is characterized by a number that is assigned to the product in accordance with the Technical Conditions for the production of such products. In accordance with the technical specifications, fiberglass reinforcing bars are today produced under the following numbers: 4; 5; 5.5; 6; 7; 8; 10; 12; 14; 16; 18. The weight of a linear meter of fiberglass reinforcing bars available on the modern market varies between 0.02–0.42 kg.

Types of fiberglass reinforcement and areas of its application

The fittings for the production of which fiberglass is used have many varieties, differing not only in diameter and profile shape (smooth and corrugated), but also in area of use. Thus, experts distinguish fiberglass reinforcement:

- working;

- installation room;

- distribution;

- specially designed for reinforcing concrete structures.

Depending on the tasks being solved, such fittings can be used in the form of:

- piece rods;

- elements of reinforcing mesh;

- reinforcement frames of various designs and dimensions.

Despite the fact that reinforcement made of fiberglass has recently appeared on the domestic market, enterprises, construction companies and individuals are already quite actively using it to solve various problems. Thus, the use of fiberglass reinforcement in construction is gaining popularity. It is used to reinforce foundations and other concrete structures (drainage wells, walls, etc.), and is used to strengthen masonry made from brick and block materials. The technical characteristics of fiberglass reinforcement allow it to be successfully used in road construction: for reinforcing road surfaces, strengthening embankments and weak foundations, and creating monolithic concrete foundations.

Individuals who are independently engaged in construction on their own plots or in their country houses have also managed to appreciate the advantages of this material. An interesting experience is the use of fiberglass reinforcement in dachas and in the gardens of private houses as arcs for the construction of greenhouses. On the Internet you can find many photos of such neat and reliable structures that are not subject to corrosion, are easy to install and just as easy to dismantle.

The big advantage of using such material (especially for individuals) is the ease of transportation. Fiberglass reinforcement rolled into a compact coil can be transported even in a passenger car, which cannot be said about metal products.

Which is better - fiberglass or steel?

To answer the question of which reinforcement is better to use - steel or fiberglass - you should compare the main parameters of these materials.

- If reinforcing bars made of steel have both elasticity and plasticity, then fiberglass products have only elasticity.

- In terms of tensile strength, fiberglass products are significantly superior to metal ones: 1300 and 390 MPa, respectively.

- Glass fiber is also more preferable in terms of thermal conductivity: 0.35 W/m*C0 - versus 46 for steel.

- The density of steel reinforcing bars is 7850 kg/m3, and that of fiberglass is 1900 kg/m3.

- Fiberglass products, unlike steel reinforcing bars, have exceptional corrosion resistance.

- Fiberglass is a dielectric material, so products made from it do not conduct electric current and are absolutely transparent to electromagnetic waves, which is especially important when constructing structures for certain purposes (laboratories, research centers, etc.).

Meanwhile, fiberglass products do not work well in bending, which limits their use for reinforcing floor slabs and other heavily loaded concrete structures. The economic feasibility of using reinforcing bars made from composite materials also lies in the fact that you can purchase exactly the quantity you need, which makes their use virtually waste-free.

Let's summarize all of the above. Even taking into account all the unique characteristics of composite reinforcement, it should be used very carefully and only in those areas where this material performs best. It is undesirable to use such reinforcement to strengthen concrete structures, which during operation will experience very serious loads that can cause its destruction. In all other cases, the use of fiberglass reinforcement and other composite materials has proven its effectiveness.