Do-it-yourself chipboard rack for home. How to assemble a rack with the right dimensions at home Make a rack for things

Tidying up even a small room is not as easy as it seems. Especially if it is cluttered with a lot of things. Roomy racks will help clear space and organize chaos. The design is universal in nature - it can be installed in any room, and it will look organic. To find out how to make a rack with your own hands, you need to understand the types and materials of this structure.

Many people think of the word shelving as a metal unpretentious structure used mainly in warehouses. But such furniture is used only on a production scale or in garages. They must meet the following indicators:

- high functionality: the more capacity, the better;

- strength - the best metal racks for storage rooms and garages, they are durable and unpretentious;

- easy maintenance - furniture made of porous materials or with an expensive paint coating requires delicate handling, therefore it is better to use wood and similar materials in technical rooms.

However, I would like to make the shelving in living rooms more original. You should not limit your imagination when creating such designs. Indeed, in addition to the main function, the rack can become a worthy decoration of the entire room.

Bottle rack

If you want to build a rack in the kitchen, you should take a closer look at the bottle design. It will appeal to collectors and connoisseurs of alcohol. To create a rack, a solid solid wood and bottles of the same shape and height are used. To give the wood a noble shade, various impregnations and stains are used.

Note! Dark wood looks very noble with green glass bottles. And to give wood a vintage touch, you can use artificial aging and firing.

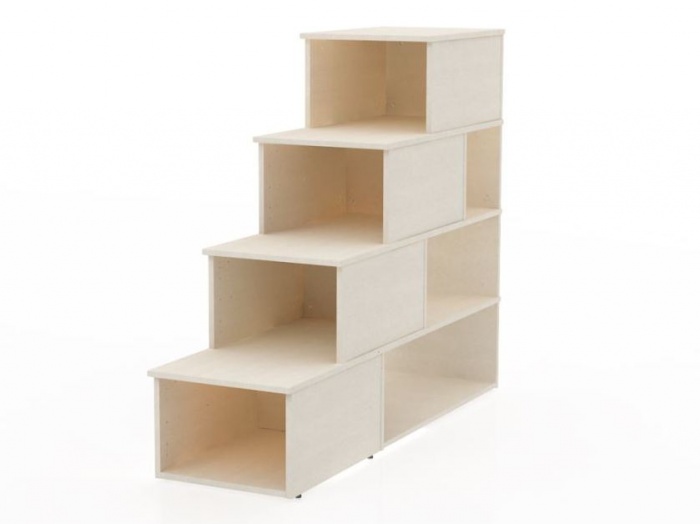

Shelving ladder

In large houses or two-story apartments, staircases occupy a large space. To save valuable space, this interior detail can be combined with a rack. Hollow boxes made of solid wood or chip materials will hold a lot of small things. Many book lovers keep their favorite volumes in these lockers. And the ladder is used as a cozy seat when reading. For greater functionality, the drawers can be supplemented with original doors.

If you already have a staircase in your house, and you do not intend to remodel it, then the rack can be placed directly under it. Create a structure that follows the outlines of the steps. The distance between the vertical struts of the frame should be equal to the width of the steps. This will create an organic composition.

Suspended structure

For those who do not want to spend a lot of time and money on a rack, a suspended structure is suitable. It represents shelves strung on a string. It is not used for storing heavy objects, but for small trinkets it is quite.

Glass racks look very interesting in a similar style. Shelves made of colored and transparent glass are strung on metal cables, and beads or decorative supports are strung at a distance between them.

Steampunk furniture

Fans of steampunk style will appreciate the shelving made of water pipes and fittings. The frame of the structure is assembled from them, and a solid array is used for the shelves. The rack will organically fit into interiors in the style:

- loft;

- steampunk;

- industrial, etc.

However, if you keep the furniture in restrained colors, then it will perfectly complement both the kitchen and the living room. Shelving of this type perfectly saves space due to the absence of rear uprights. The structure is fixed on one bar from above and to the floor. The shelves are strung on the racks one by one. Even an unprepared person can assemble such a rack with his own hands.

Note!If you want to create a steampunk design, use copper paint for the frame.

Project creation

Before starting work, outline the appearance and parameters of the future design. For this, a piece of paper or editors for design are suitable. Before building a drawing, you must consider the following parameters:

- the height and width of the room in which the rack will stand;

- size and weight of items given for storage;

- room humidity level.

The structure of the rack is very simple: it consists of a frame and shelves. Wood and metal are most often used as the outer frame. If the rack will be located in a room with high humidity, moisture-resistant types of wood, plastic or glass are used for the shelves. The metal frame is coated with anti-corrosion compounds to protect it from rust.

Important! In rooms where contact with moisture cannot be avoided, it is not recommended to use wood for the frame.

When you have decided on the purpose and location of the future rack, you can start measuring. They measure the height of items that are planned to be stored on the shelves, and add another 7-10 cm to the value.

Consider correct weight distribution. The heaviest and most voluminous items are placed on the lower shelves. The higher the shelf, the lighter the things stored on it should be. At the very top, they put various boxes, boxes and more.

The racks on which it is planned to store books or jars with blanks, the legs should be placed close (half a meter ± 10 cm). If a metal profile is used for the frame, the step is increased to a meter.

Creating a simple wood and metal shelving unit

If you need simple and spacious shelving for a dressing room or pantry, use a simple structure made of wood and OSB. For the frame, a square beam with a side of 5 cm is suitable.If you are ready to spend more money on the construction, replace the OSB plate with an array.

Assembly stages

The instructions for creating a rack includes the following steps:

- cutting a bar - the material is cut for the frame according to the drawing;

- using self-tapping screws or nails, a rectangular frame is assembled, the assembly starts from the bottom corner;

- the frame is attached to the wall with metal fasteners and self-tapping screws;

- mark and saw OSB slabs for future shelves;

- the shelves are laid on the crossbars of the frame and fixed on nails or screws.

Note! Self-tapping screws are more durable fasteners.

Location of crossbars

If the vertical posts are located close to each other, the structure does not need cross members. This function will be performed by a thick OSB plate. If you want to create a more stable structure, you cannot do without crossbars. To do this, you need to install longitudinal bars under each shelf. You can get by with one, but most often they use a pair of crossbars.

Important! To increase the strength of the structure, diagonal beams are attached to the rear wall.

Metal shelving

To assemble a metal rack, you need a welding machine or an electric drill. The welded construction looks neater and is more reliable than the prefab. If you do not have such tools, it is better to give preference to wooden furniture.

Instructions for assembling a metal rack practically does not differ from the manufacture of a wooden one. The first stage consists of assembling the frame and fixing the structure to the wall. If weighty materials are used for the shelves, then the crossbars are not needed.

Note! To create a rack, it is better to purchase a metal profile, not a corner. It is more convenient to assemble and maintain.

As a material for a slave, a tubular metal profile of a square section with a side of 25 mm and a metal thickness of 2 mm is used. If a corner is used, the optimal size is 40 by 40.

For the manufacture of lightweight structures, support metal brackets are used. Dowels or self-tapping screws are used as fasteners. Shelves are laid on top of the brackets.

A lightweight design can be made using metal support brackets. They are fixed with dowels to the wall, and shelves from a board or OSB board are placed on top.

If you want to know more about the manufacture of a rack, watch the video instruction. From it you will learn the tricks of construction and will be able to assemble a durable and functional structure.

The rack is a very common household item. Its main advantage is ergonomic and aesthetic: it is "airy", visually does not compress the space of the room much, which is essential in small apartments, and when zoning a room and in housing of any class. Shelving designs are not complicated, they do not require a lot of work, and at least for those who live in budget houses it makes perfect sense to build them on their own.

To make a rack with your own hands, you must first of all decide on its purpose. In addition to purely utilitarian shelving in garages, basements, workshops, on balconies (which will also be given due attention later), in living quarters, shelves are used mainly as general-purpose storage facilities for small items, pos. 1 in fig. In second place in terms of demand are book shelves, pos. 2. Second-hand booksellers and librarians know very well that a book must breathe and will not live long in a closed cabinet.

This is followed by corner racks (item 3) in a restless corner, which sooner or later forms in any habitable apartment. With the help of a rack, you can arrange a work corner, a mini-boudoir, etc. Finally, a bookcase rack for space zoning, pos. 4, and a rack-cabinet in cases where, using an ordinary cabinet, you would often have to open several doors at once, pos. 5.

Note: racks for special purposes - for toys, in the kitchen, for flowers, tools, etc. - do not fit into the household classification and will be considered separately.

The latter cases are the most difficult from the point of view of furniture design. The zoning rack should be particularly strong, stable, and preferably anchored to the floor, ceiling and adjacent wall. A rack cabinet, in order to be equal in strength to its body counterpart, must, firstly, contain a central rigid box in the power circuit (possibly not of full height); secondly, its side sections must be strictly symmetrical, as shown in fig.

Power circuits

Wooden

A wooden rack most often does not have rear paneling and solid vertical partitions, therefore its proper reliability is achieved by somewhat different means than with cabinet furniture. Box-shaped racks have a fairly strong and openwork structure. Their sidewalls are not necessarily solid shields, they can be stacked from flexible rods (broom effect) or beams and rails, pos. 1 and 2 in Fig. These racks are most suitable for zoning.

Where appearance is not important, and the workloads are small (linen, shoes, etc.), it is better to make a frame rack, pos. 3; these are the least labor and material intensive. The loaded shelves in them can be included in the power circuit at any place vertically and therefore they can be rearranged.

The racks of the beam scheme (pos. 4) are externally similar to the frame ones, and the shelves in can also be arranged according to the contents, but the frame itself works in a different way and is much stronger: beam racks from materials available to the home craftsman are capable of carrying a load of up to about 800 kg per linear meter shelf length. The price is higher than that of frame ones, laboriousness and material consumption.

A cantilever wooden rack does not have separate load-bearing, distributing and load-bearing elements; it is, in general, a complexly fractured strip of material, in which the loads spread out as necessary. It can have the most fanciful configuration and therefore cantilever racks are widespread in stylish interior design. However, they are suitable only for light things and more or less durable are only angular, pos. 5, or reinforced with metal pipes, see below. However, the cantilever shelving gave rise to modular shelving, which, with no less aesthetic advantages and the possibility of flexible layout, are quite durable.

Modular racks are all-assembled and stacked. The basis of the first 3 elements: grille, pos. 7, box, pos. 8, and a ladder, pos. 9. Of these, you can type products of the most bizarre type, it would be a fantasy, and the step of the dimensional grid when designing is the same. A hybrid stands apart in this row: a lattice of boxes assembled by a ladder, rotated 45 degrees, pos. 9. The durability is exceptional, from modules of this type you can type long, with corners, room dividers, without picking the floor with the ceiling.

Type-setting modular racks are made of flat (pos. 10) and volumetric, pos. 11, modules. Flat in this case does not mean that they are completely devoid of volume, but that there is a useful volume, i.e. capacity themselves do not have. Flat elements of type-setting racks, as a rule, have a complex configuration and are purchased ready-made. On their own, amateurs most of all make typesetting racks from bulk modules-boxes. The modules are connected with double-sided tape, Velcro, pairs of clothing buttons, etc.

Relatives of the lattice module cantilever racks, i.e. with overhanging shelves, pos. 12. They are the most "airy", so they are usually placed in a small hallway. One of the design options for a cantilever rack in the hallway is shown in Fig. on right. Racks of pipes can be replaced with laminated chipboard plates or boards with a section of 150x18 mm, located as in pos. 12.

The box module gave rise to transformer racks of the "Varna" type, pos. 13. There is no transformation mechanism, as well as hinges: “Varna” is simply put in the right way. The required rigidity is ensured by the presence of a strong back wall for all boxes and the choice of material - laminated chipboard of class E1.

In the workshop and at the warehouse of the craftsman-IP, a bridge rack, pos. 14. With an equal bearing capacity with a beam, it is less material-intensive, concentrated loads can be put in the middle of the A-shaped racks, and a lengthy one can be placed on top. In everyday life, a rack-bridge is also able to find a place for itself. Look, for example, what kind of rack was made by people endowed with imagination and ingenuity, from a pair of old crutches, pos. 15. Crutches, by the way, can be replaced with 15-20 mm thick slats made of solid, durable and resilient wood: oak, beech, hornbeam, birch.

Note: the same rack is also suitable for flowers (see below), because its structural elements are not very conspicuous.

On metal

Metal is more resilient than wood and subject to plastic deformation, which is why it is generally more difficult to calculate and create spatial structures from it than wood. Therefore, a metal rack is built without taking into account the interaction of the base with the shelves, which can be of any material. Metal racks are assembled mainly according to the least material-intensive frame and console schemes, since metal is stronger than wood.

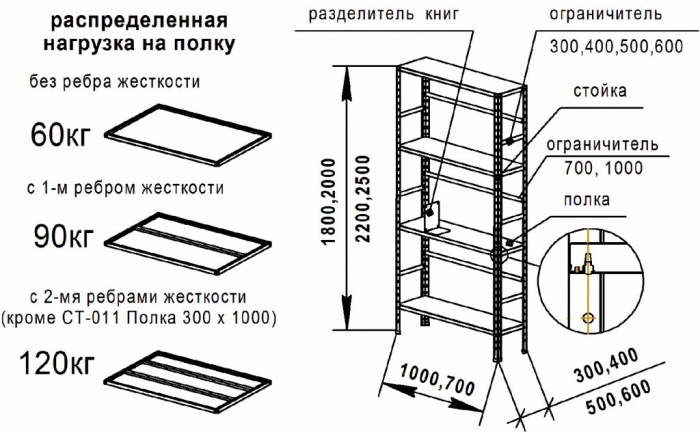

Heavy, cumbersome, costly, requiring hard locksmithing and welding, racks from a corner or professional pipes are still being made, probably by inertia. These days it is easier, easier and cheaper to assemble a rack from a profile. Special thin-walled shelving, it is available in a wide range. You will need a perforated profile for the racks and a solid corrugated one for the shelf frames. The parts are fastened with self-tapping screws, and during assembly they are held in place with clamps, pos. 1 in fig. The structure is protected from skewing by X-shaped ties at the back, pos. 2; a special profile is produced for them. Such racks hold a load of 400 or more kg / r. m, and the frame is assembled by 1 person for an hour or two.

For a balcony, the load-bearing capacity of a rack made from a special profile is excessive. Balconies / loggias are designed for a load of 1.2-1.6 tf; glazing gives several hundred kgf, and even furniture, people. So the shelving on the balcony can and should be made easier, lighter and cheaper.

This is where the profile for product racks comes in handy, the so-called. trade. For a conventional balcony approx. 1 m, a pair of vertical U-shaped ties with brackets, pos. 3. Under maximum load - 3-4 verticals. A wide assortment of fittings is sold to the trade profile, but, in addition to verticals, we only need brackets. They are produced with the number of setting paws from 2 to 5, but since there will still not be socks-panties on the rack, you need to take at least 3-pawed ones; highlighted in color at pos. 4. The verticals are fixed to the wall with self-tapping screws (4,2-6) x (60-80) in propylene dowels with a pitch of 70-150 mm, and the brackets are simply inserted into the profile.

About pipes in racks ...

Racks based on industrially manufactured pipes are quite expensive, because shaped fittings and fasteners are used, on the left in Fig. They look a little dryish, so they put them most of all in offices. Amateurs most often reinforce cantilever racks with pipe inserts in the center. In this case, support heels are purchased ready-made or milled to order.

To pull off the inserts, oak or, better, propylene corks are pushed into them at the ends. In the first case, the seam between the pipe and the plug is spilled with superglue (cyanoacrylate), and in the second case, oblique notches are made on the inside of the pipe with a needle file and a plug with a diameter slightly larger than the inner diameter of the pipe is pressed in, heated with promfen until plasticity begins. More precisely, the pipe is pressed on: as soon as the cork began to soften, it is placed on a hard surface and a pipe heated in the same stream from a hair dryer is pushed onto it. In any case, everything is pulled together with self-tapping screws.

If the design requires the connection of pipes in parallel and butt (T-shaped), as on the right in the figure, it is not at all necessary to spend money on shaped clamps. In parallel, the pipes are connected simply with self-tapping screws for metal, and end-to-end - as described above, with a plug.

... and about the pipe rack

A special case is the shelving in the cellar. Steel rusts, wood decays and molds. Here a rack of pipes is most of all in place, only not of steel, but of water-supply propylene. How to make a PP pipe rack in a cellar, see the video below.

Video: do-it-yourself pipe rack (plastic)

Connections

Hidden connections on dowels, in a blind spike / groove, and other furniture in the shelves are not reliable enough, and nothing really holds on to the dowels. The reason is an insufficient number of intersecting stiffness bonds in combination with a small support area and a high center of gravity (CG).

If the rack is in the utility / utility room, it's okay: they are connected with self-tapping screws, steel corners, etc. with metal fasteners. But above shelving for living spaces, you have to tweak to hide more reliable open connections. For racks on a frame, the simplest way is to hide the fastener heads under the shelves, on the left in the figure, due to their (shelves) removal over the support frames. The front edges are then refined with laminated chipboard strips on dowels, as described below.

If the rack is assembled entirely from boards or plywood, then its parts cut into each other by half, as on the right in Fig. Note that the grooves in the shelves are made at the back. Then the vertical posts will keep their front edges from sagging, and the rear ones will be made of diamond-shaped pads of about 70x70 mm made of any sufficiently strong material: plywood, plastic, metal.

In the case when the rack has an integral frame along the contour, it is best to replace individual "pyataks" with a solid sheet of 4-6 mm fiberboard. Then the extreme parts are made wider by the thickness of the fiberboard, a fold is chosen in them and the sheets of the back sheathing are fixed with small screws with press washers. Each corner and crosshair should have a piece of hardware, and between them - with a pitch of 70-250 mm, so that they are evenly distributed.

Note: in some cases (see below) a modular cardboard rack will work well. Then there is no need to fiddle around, reinforcing the glue joints with wooden studs, as, for example. in cardboard shelves: horizontal and vertical parts cut into each other by half, as in Fig. Glued with PVA, such a joint is quite reliable.

About the base

Does the rack need a plinth? A must, and not just for hygiene. Especially the kitchen one, which is pushed more often, and is stored in it wet, beating, greasy, loose.

In a rack without a plinth or with a plinth without a forward projection, the projection of its CPU falls on the support center (CO). In case of accidental impact, the overturning moment will be directed anywhere, on the left in Fig. If the base is with an extension of at least 7-10 cm, then the overturning moment is always directed to the wall, in the center. An example of a rack in the kitchen, made with this in mind, is shown on the right, and due to the skillfully chosen design, the removal of the base is invisible.

Various racks

Garage

The first place where you cannot do without a rack is a garage, at least for seasonal tires. You can't keep it thrown at random. However, the standard garage width of 4 m is not at all superfluous if the car doors are opened. Therefore, a garage rack, in addition to strength and convenience, should be compact. Drawings of one of the options are shown in Fig. All parts, including the hinges of the shelves, are made independently from 30x30 timber, plywood and 6-8 mm steel bar.

And in fig. on the right - a rack for a garage is not folding, but modular made of waste material: scraps of boards, plywood, timber. It is not necessary to connect them with through bolts; apparently, the author of the design had an abundance of them. Self-tapping screws will also go, they need to be wrapped from the plywood / board side into a bar. It is better to make 4 failures from above, according to the number of replaceable tires.

Book

Books give a significant and, what is important, stable static load. A collection of 3500 volumes (in an ordinary apartment without prejudice to everyday conveniences it can fit even more) takes about a ton. Therefore, the book rack should be:

- Durable.

- On the plinth, with or without removal - the ingress of moisture on the books during cleaning should be excluded.

- From plywood from 18 mm or solid boards from 24 mm - chipboard does not hold a long-term static load, bends.

How the bookcase works is shown in the figure below. In the power circuit, in addition to the base, bottom and roof, at least 2 solidly fixed shelves are constantly tied, evenly spaced in height. The cuts for adjustable cuts are located in increments of 5 ", which is equal to twice the size of the polygraphic module. This allows volumes from folio to in duodecimo to be placed, and pocket editions are stored separately in a mini-rack; possibly cardboard.

Key manufacturing points are given on the right in the same fig:

- The backdrop is sewn up with fiberboard so that the books and the wall do not wear out;

- The sides, on plywood pads, are sheathed with chipboard or a second layer of plywood, 2 flat boxes are obtained, bringing the overall rigidity to the required;

- Decorative overlays with a height of 100-150 mm are applied to the edges on dowels in milled grooves and glue. In addition to the stiffness of the shelves for deflection, the linings provide a microclimate on the shelves favorable for books.

Note: the width of the shelves is approx. 30 cm. Storing books in 2 rows is inconvenient and not useful for them.

Toy

Children need to explore the world to become adults. The easiest way to explore is to break open and see what's inside. Or what will happen, in addition to being harassed and punished, which goes without saying. With this in mind, a children's toy rack can be made in 2 ways.

The first one is “foolproof”, the rack is especially durable. An example of a practical design of this kind is on the left in the figure: a symmetrical shelving unit with a plywood backdrop.

The second is to give him / them free rein and let them break it. But with a sense, so that intelligence, coordination of movements, spatial imagination and, in general, the ability to handle things develop. Here, the optimum is a modular collapsible rack, on the right in the figure, let them configure themselves in their own way.

In order not to feel sorry, they will suddenly completely break, and so that they themselves are not injured, the parts are made similar to cardboard shelves:

- Spread a polyethylene (PE) film on a flat surface;

- Raw materials (original sheets) are laid out on it and impregnated with a water-polymer emulsion (VPE);

- When dry, turn over and soak on the other side;

- Blanks (plates) for parts are cut with an inner corrugation of the cardboard oriented mutually perpendicular in adjacent layers;

- The corrugations of the outer layers should be oriented along the long side of the part;

- If there are 5 layers, then the corrugations are oriented with a turn of 45 degrees: 0 (along) - 45 (obliquely) - 90 (across) - 135 (obliquely in the opposite direction) - 180 (along again);

- PVA is glued all at once without exposure to tack and covered with PE film;

- Withstand 2-3 days under a small, 3-5 kg \u200b\u200b/ sq. m, oppression evenly distributed over the surface, books, stacks of old newspapers, magazines, etc. are convenient for this.

Shoe

From the point of view of the safety and wear of shoes (which at current prices from the point of view of the budget is clearly felt), you need 2 racks for shoes: in a small "dirty" shoe, it will "shake" before cleaning, otherwise dust / dirt will rub into the leather / fabric, which will seriously reduce her service life. Grains of sand are especially harmful here. Then, in a “clean” larger rack, shoes that are out of season or not very common are stored in conditions conducive to their durability.

There are no problems with "dirty" shelving, it is a small box with lattice shelves, even rope ones, as in fig. “Clean” can be a shoe rack or a shoe cabinet with folding shelves in the hallway. However, if the house can be fenced off if not a dressing room, but at least some nook with an even microclimate, this will only make shoes better.

A drawing of a rack for long-term storage of shoes is shown on the next. fig. Construction - economical frame made of 20x20 slats; lattice type-setting shelves. If you remove 1 section 375 wide, this rack will fit even in the closets of the infamous Khrushchev kopeck piece.

Instrumental

The simplest tool rack is a board with clips where tools are put in, nails / hooks and hangers, on which they are attached, on the left in Fig. For small tools - a board with holes, where they are inserted by handles, in the center. But much more economical and practical is the old-fashioned way to make a tool rack from trimming boards and pieces of rubber (preferably reinforced dyurite) hose on the right. And it is safer: the likelihood that the tool will fall out and have a blade on the leg or prick the hand on the lips is almost zero.

Floral

A rack for indoor plants should, firstly, open them all to the light; secondly, visibly not to replace flowers and greenery. Single-column racks (two positions on the left in the figure) are "generally airy", but their openwork appearance is quite difficult technologically and their stability is low. Much simpler and more reliable is a bookcase for flowers, 1- and 2-sided, two pos. on right.

It is more difficult, but it allows you to place more plants on the same area and the pyramid bookcase is almost invisible behind them, pos. 1 in fig. on right. If you spend more on material and make it solid from plywood, as in pos. 2, it will be possible to keep even antagonist plants in one place, i.e. intolerant of neighborhood with each other.

Many keep flowers on their balconies, even setting up greenhouses for orchids there. In this case, whatnot will come in handy, the drawings of which are given on the left on the next. fig. The space inside the rack is not wasted there: a weak, 50-80 W, electric heater is placed in it, heating mainly with thermal radiation. It can be made from 2-3 25 W incandescent lamps, covered with a galvanized casing. It is the lack of root heating (the roots get cold, catch a cold and stop feeding the vegetative parts) that explains most of the failures of the balcony plant culture. And from such a rack, when illuminated with Flora or LD lamps, you can get cucumbers, strawberries, even tomatoes all winter

Note: on the right in the same fig. - portable spring flower rack for giving. Can serve as a greenhouse.

For violets

Violets in this case are not forest and not pansies, but not at all related to them Saintpaulias from the Gesneriaceae family. Uzambara violets, or simply violets, were nicknamed by their homeland - the Uzambara mountains in South Africa. Due to its grace, diminutiveness and abundance of varieties, Saintpaulias have become, and quite deservedly, literally cult plants.

The culture of the Gesneriaceae, among which there are many that give odds to orchids, is a special topic. But from a technical point of view, the rack for violets should be moisture resistant, chemically absolutely and absolutely neutral and allow placing illuminators: the culture of Saintpaulias is better not on the window, but with even illumination by the LDC lamps, on the left in Fig.

The shelves of the homemade shelving unit for the Saintpaulias collection can be made by gluing 2 pieces of PVC box for electrical communications, 150 mm wide, in the center. They also serve as good light diffusers. They are glued with an assembly "Moment"; Dichloroethane glue (not pure dichloroethane!) is highly toxic and requires special precautions.

Assemble a rack for violets on PP pipe lengths approx. 400 mm with inserts from the same pipes of a smaller diameter and self-tapping screws. Self-tapping screws are driven in with heating:

- Drill holes for them with a diameter along the body of the hardware without thread.

- Screw in until it fits snugly and evenly.

- The heads of the hardware are heated with a soldering iron (ordinary, electrical) until the plastic around it slightly bubbles.

- Screw in quickly until the head is recessed.

- For stability, the joints of the assembled rack are carefully drilled with superglue.

For seedlings

Racks for seedlings, especially in the commercial economy, have a number of design features in comparison with flower household ones. Which ones and how to make a seedling rack, see the video.

Video: DIY seedling rack

Whatever technological innovations and design solutions modern furniture manufacturers offer us, shelving has been one of the best solutions for many years. Moreover, we are talking not only about convenience, but also about the aesthetic component, because they can be entered into the interior of any apartment, house or even a garage. If you want to create an unusual and practical do-it-yourself rack for flowers or books, then you don't need to have any carpentry skills. It is enough to prepare the necessary materials, as well as be patient.

Experienced furniture makers know firsthand that in fact any cabinet is a rack with a back wall and doors. Therefore, having mastered the simple technology of assembling flower racks, you can easily make a full-fledged cabinet of any size.

How to determine the dimensions

Chipboard, MDF or plywood up to 20 mm thick are most often used to create a flower rack. Also, the boards that were used for. By the way, natural wood boards will be much better than plywood or chipboard.

The width of the shelves must be selected based on what you plan to store on them. So, shelves with a width of 250-300 mm are quite suitable for books or flowers. But for car tires or, for example, a tool, the width should be greater - up to 700 mm.

As for the length of future shelves, the choice here also depends on what you plan to store on them. For light items (for example, for souvenirs or soft toys), a wooden shelf up to 1500 mm long is suitable. But to store volumes of books, you have to reduce the length of the shelf to 80 cm. Otherwise, the shelf may bend under the weight of things. If you plan to place a future rack in the garage for placing heavy objects on it, then it is better to reinforce the shelves with metal corners or other amplifiers.

The size of the future rack, as well as the expected load on the shelves, determines the set of necessary fasteners. So, self-tapping screws for concrete up to 90 mm long are suitable for lightweight structures. For brickwork, it is best to use self-tapping dowels up to 52 mm in length. But for an overall and heavy rack in the garage, it is necessary to additionally strengthen the structure with anchors or hooks.

How to make a rack with your own hands

- Screwdriver (ideally a screwdriver);

- Dowels, self-tapping screws (length depends on the type of wall);

- The shelves themselves (the suitable material is described above, we will give an example of creating a wooden rack with shelves 19x305x183 mm in size);

- Support beam 38x89x390 mm in size;

- Slats 19x38x1830 mm in the amount of 10 pieces - necessary to create crossbars and planks;

- Reiki 19x38x203 mm - required to create racks.

Rack with shelves

Creating a rack with your own hands begins with the installation of strips, to which fasteners will be made. It starts with the markings on the wall. You need to draw five horizontal lines 183 cm long on the wall. The lowest one should be 39 cm high from the floor level. The distance between the others should be 41 cm. This will be a sketch of the location of future flower shelves.

In the event that your garage or room is made of plasterboard, then you need to locate the main profile in order to carry out the fastening of the entire structure to it. Use a special search engine or a simple magnet for this. Then mark the wall where the profile will intersect with the shelves.

Now cut the planks and crossbars to the required size. There will be five of them in total. Now each plank must be fixed in the place where you have already put the mark (they are mounted on the drywall profile). To secure the crossbars in the places where the planks pass, drill holes and secure the structure with self-tapping screws.

When the installation of the "skeleton" of the rack is completed, proceed to collecting the shelves. To get started, cut out three racks and prepare a support bar (it can be removed later). Now you need to calculate the length of the rail that will connect the edge of the shelf to the wall. This can be done according to the formula a2 \u003d b2 + c2, where a is the length of the crossbar itself, b and c are the height and width of the shelf itself. If you plan to make a rack of the same dimensions as in our example, then the rail will turn out to be 511 mm in length.

Secure the resulting rail at the intersection of the bar and the post. Use self-tapping screws for this. To increase the strength of the structure, professionals recommend additionally processing all parts with glue.

Now it remains to fix the shelf. This will also require screws and glue. Please note that when using boards, it is recommended to drill holes with a smaller diameter than self-tapping screws. This will prevent the material from splitting or deforming. Repeat the procedure for everyone and your design is ready.

There are other types of shelving. For example, a shelving unit with side walls. Such designs are reminiscent of bookcases. They differ from conventional shelving in greater strength and the ability to store heavier items. Also, designers often use such pieces of furniture for dividing zones or in large rooms.

For a wooden rack, you will have to additionally prepare a roller or brush, a sander and a spatula - this is necessary for additional painting work.

The shelf unit with side walls is fixed to a base (use boards up to 50 mm thick), which must also be fixed to the wall. Since the walls in our houses are far from always even, measurements should be taken at the bottom, top, and also in the middle of the wall.

After installing the base, proceed with the assembly of the rack. To do this, prepare the side walls, install shelves in them, and then mount the structure on the base. As a result, you get a wardrobe without doors.

Conventional cantilever racks are suitable for a garage, kitchen or closet as they provide open access to the items stored there. with side walls will be an excellent solution for the living room or nursery. It can be used to store books, souvenirs, toys or boxes with small things.

As you can see, making a rack with your own hands is not so difficult. It is enough to prepare all the necessary materials. If you already have experience in creating such structures, share the comments below this article.

Recently, I was faced with the task of purchasing a bookcase. Approximately the same design as in the photo below. 180 cm high, 80 cm wide and 30 cm deep. Naturally, the first thing I did was go to the shops, but the minimum price without delivery of 2,700 rubles surprised me: it was too expensive. It seemed to me that such a rack can be purchased in the region of 1000 rubles.

And then they suggested to me the idea of \u200b\u200bself-assembly. No sooner said than done. And it turned out that it is not only easy, but also interesting!

The fact is that the main material for such racks is laminated chipboard (LSD chipboard), 16 mm thick. Accordingly, the first step was to determine the size of the parts and find a place where all this can be cut.

Rack dimensions

It is easy to see that the rack I need consists of 9 large parts: 2 side walls, 6 transverse shelves and a white wall. Color - light beech.

As I wrote above, I needed a rack 1800 * 800 * 300 mm. Accordingly, the dimensions of the parts were as follows:

2 side walls - 1800 * 300 mm.

6 transverse shelves - 80 * 30 cm (I advise you to order this way, and not repeat my mistake: I ordered 4 out of 6 shelves measuring 798 * 300 mm.)

1 wall made of white fiberboard - 1750 * 830 mm.

The place where you can buy it all

In principle, it is enough to type in a search engine "sawn chipboard" and understand where is better and cheaper. In Petrozavodsk, for example, the company "Laminat Monza" is engaged in this at Kooperativnaya, 6 - http://mzptz.ru/.

I went there. Unfortunately, they do not cut the cut right away, you have to wait several days.

Arriving a couple of days later with a friend in a car (after all, the parts are quite large and difficult), I paid 1485 rubles for the above.

But that was not all the waste. Additional one had to be bought:

16 shelf supports 5 mm each. Better to buy more for stock. 1 piece \u003d 35 kopecks.

8 hexagonal ties 6,3 * 50 mm - it is also better to buy more in stock. 1 pc \u003d 67 kopecks

And self-adhesive plugs so that the place where we drilled can be sealed.

I also bought 10 meters of "light beech" edging at the guys' warehouse. 1 meter \u003d 7 rubles.

In total, the additional parts cost me 100 rubles.

Total for the cost of materials, the rack cost 1,585 rubles. If necessary, you can add the cost of delivery of materials here. Thus, the materials are almost twice as cheap as in the store!

Assembly

And now the fun part. Rack assembly. Here, in fact, are the plates themselves.

If you look closer, they look like this: pressed wood chips from the sides. So that this is not visible - we glue the edge.

First step assembly of the rack - glue the edge. First we do it with the shelves. Here it is enough to glue only one side, because the rest will be hidden. I advise you to practice first. So, we firmly install the stove so that it does not stagger.

Next we take .... iron! Yes Yes. It turns out that the edge is glued with an iron (heat). Cut off the required piece of the edge, set it straight.

And carefully, constantly making sure that the edge does not slide out, we run it with an iron. As a result of a chemical reaction, the edge is tightly glued to the end of the board.

Since it is wider than the plate, we take a thin knife and cut off the excess. It is important to do everything smoothly. In fact, this is the most difficult stage, but you quickly understand how to hold the knife. Later, you can take fine sandpaper and remove the bumps.

We do the same with two side walls, only we glue two sides: the front and the top.

I highly recommend watching the video of how the edge is glued - http://www.youtube.com/watch?v\u003dR2oL9Jaq62I

Second phase - we drill recesses for the shelf supports. To do this, we select a drill of a suitable thickness and outline the recesses (i.e. we do not drill through and through, but to the length of the shelf holders). In fact, they mean the distances at which our shelves will be. This is the beauty of self-assembly - you decide what you need and how you need it.

What we did on one wall - we also do on the second.

Stage three - we drill holes for screeds. Ties connect the side walls with the upper and lower shelf (if you wish, you can do it in the middle). I recommend retreating 5-10 centimeters for the lowest shelf.

In the upper and lower shelves, we drill holes for the screeds and tighten them.

As a result, we get such a frame.

Stage four - we attach the back wall. It is not difficult. A white sheet of fiberboard is simply placed around the perimeter and attached to the frame. I tried to attach it to a construction stapler, but it did not hold well, so I nailed it with small nails,

Fifth stage - we insert the shelf supports into the recesses, install the shelves, glue the plugs and rejoice :)

That, in fact, is all. And this rack will serve as the basis for our online store -

In small apartments, the problem of lack of space for storing certain items often arises. If in a large living space you can equip a pantry or a closet, then a small apartment excludes such an opportunity. The easiest solution is to install a wooden rack.

But it will be useful not only in the apartment, but also on the balcony, where often a lot of everything is stored in the garage, where car accessories and tools must be laid out in places so as not to waste time constantly searching for them. It is very interesting to enter a shelving structure for zoning space, for example, in a studio apartment.

Despite the fact that even a beginner can do the shelving, there are still some nuances, the observance of which will help create a high-quality piece of furniture at a minimum cost.

Varieties of wooden shelving

Wooden shelving is a structure consisting of several shelves fixed to a support board. Their number depends only on the desire and capabilities of the owner. Prefabricated wooden racks will perfectly fit into any interior and will help you store various items, for example, books, dishes, souvenirs, and more.

The functionality of those rooms where this piece of furniture can be placed is very diverse

It is very convenient to install racks in the nursery, where, due to the availability of free space and the openness of the shelves, the child can place all his toys and take them out without the participation of adults.

In the office, the structure will serve not only as a place for storing documents, but will also become an excellent decorative element of the workplace.

For the kitchen, a rack is a must. Dishes can be stored there, as well as neatly placed containers with bulk products.

On the balcony, a wooden rack is used to accommodate seedlings or indoor plants in the warm season. Everyone knows that mostly plants need a little heating. Now you can buy special pieces of furniture with heated shelves, but self-made furniture can also perform this function if each shelf is covered with foam. This material stores heat and transfers it to plants.

Depending on the design, a suitable option can also be selected:

Original shelving

Such pieces of furniture should be given special attention, since they are created in accordance with an individual project that is suitable for a particular interior. Ordinary rough do-it-yourself wooden structures are only suitable for balconies or garages, but to decorate living space it is better to use something more original. For example, the rack with bottles in the form of racks shown in the photo will perfectly fit into the living room or kitchen. Despite the external instability, it can store books and even collectible bottles of wine.

Rope structures of wooden shelves for the house, which are attached to the wall with massive hooks, look interesting in the interior, especially in the marine style. On such shelves, of course, you will hardly be able to store something heavy, but small souvenirs or frames with photos are fine. It is very simple to execute such a structure, it is enough to have a thick rope and a few pieces of wood. Shelves can also be made from leftover laminate flooring.

Metal structures are suitable for modern interiors. One of these is the design of a rack with many shelves in a chaotic manner, which are interconnected by metal tubes. Due to the stiffness of the metal elements, the rear wall can be omitted.

If you plan to create a rack in a private house, then you can arrange it in the space under the stairs, as shown in the photo.

Self-made shelving

Making a wooden rack with your own hands is quite simple, if you study all the nuances of the work in advance and thoroughly prepare for it.

Project development

The creation of a project for a future structure is a very important stage that should in no case be overlooked. First of all, measurements are made of the place where the rack is planned to be located. If the rack is not intended for decorative purposes, but is used only in accordance with the storage function, then it makes sense to carry it out in a simple form. For this, the height of the wall is measured, at which the furniture will be located, and the indicator that suits the owner is calculated.

Important! In a garage, the best way to do this is to fill the entire height of the wall.

Particularly noteworthy are the parameters of the shelves for the structure, both in length and in width. Long shelves of 1.5 meters are ideal for storing light items, for example, souvenirs and toys, but cans with blanks and books require shorter ones - about 90 cm so that there is no sagging. As for the width, shelves with a width of 25 - 40 cm will be suitable for storing books and jars, as well as growing seedlings, and for tools or larger items, such that will correspond to their size are arranged.

In general, the dimensions of the shelves completely depend on what will be placed on the rack, so first you should estimate the approximate location of the items and add 10-15 cm to the calculated figures so that you can easily put and get the item.

Necessary tools

Professionals advise to use only strong and solid wood for self-manufacturing of the shelving structure. It can be pine, mahogany or oak. Materials made from pressed sawdust are not suitable for installation, since they are rather short-lived.

Important! The moisture content of the wood for the shelving should not exceed 12%.

In advance, the boards are impregnated with antiseptic impregnations and left for several days so that the solution is absorbed.

In addition to boards, you will also need to make a rack:

- Metal corners

- Shelf holders

- Bars for stuffing them into the bottom of the shelf

- Furniture legs or castors

- Self-tapping screws

- Carpentry adhesive

- Varnish or other paint and varnish material, which will be used for finishing

- Jigsaw and sander

- A hammer

- Drill with matching set of drills

- Roulette, level and pencil

Algorithm for making a wooden rack

To begin with, all the parts necessary for assembling the rack are prepared.

Prefabricated wooden racks are made starting from the bottom. For the bottom shelf, the thickest board should be chosen, into which a 3 cm self-tapping screw can freely enter. The shelf parameters are selected depending on the project, which describes all the dimensions of the future structure. Also, if the length of the shelf is large, then it is better to mount transverse bars in its lower part to give rigidity.

The next step is the installation of the side walls. For them, not solid wood, but thick plywood can be used. The side walls of the required size are cut out of it, the location of the future shelves is marked on their inner side. It should be remembered that the most often used shelf height in the structure, which is 42 and 21 cm, can be alternated to get a neat and functional rack.

Carving wood shelves. Their size should correspond to the rack and be such that the owner has the opportunity to put and remove the shelf without restrictions.

Important! The thickness of the shelves should be at least 2.5 cm, but for added strength they can be equipped with transverse bars from below.

The next step is optional and is performed only at the discretion of the wizard. If the wall, which will have the rack structure, completely suits the owner, then the back wall can not be mounted to it. If it is customary to mount the back wall, then it is cut to the size of the plywood rack and nailed to it with small nails.

All the details have been prepared, now you can start assembling the entire structure:

- The back wall is screwed onto the bottom shelf, which is the base. If it is not there, then you can immediately attach the side ones.

- But before installing the side walls, you need to install holders in the places marked for the shelves, which can be metal or plastic.

- After the side walls are attached to the base with self-tapping screws. If necessary, a metal corner can be used.

- Also, the shelves can not be held on special elements, but attached directly to the side walls. For this, the shelf is already held inside the rack by an assistant, and the second master screws in self-tapping screws from the outside. For added strength, the shelves can be supported by metal corners.

Advice! At all stages of assembling the rack, it is imperative to use the building level, which will exclude any distortions.

To create a high-quality rack design, there are several tips that are optional, but very desirable:

- The main structure of the rack can end with a top cover. This is very convenient due to the fact that the rack will become stronger, and dust will not get on the top shelf.

- For additional strength, the holes are coated with wood glue after drilling.

- If casters are used instead of regular legs, the rack can be moved. Also, the installation of these elements will help prevent skewing of the structure under heavy loads.

- If chipboard or MDF were used for the manufacture of the shelving, then their ends are processed with melamine film, which is easily glued with an iron. Such a strip is laid on the end processed with sandpaper and processed with a hot iron. Thus, the end will close and acquire an aesthetic appearance.

- For greater decorativeness, the rack can be supplemented with doors or other elements that will only decorate it.

Conclusion

A shelving unit for an apartment will become a very functional addition on which you can place memorabilia or other items. It is possible to make this piece of furniture on your own, which will allow you to save money and get exactly the design you need. This is easy to do, just read this article, which provides detailed instructions for installation.